Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

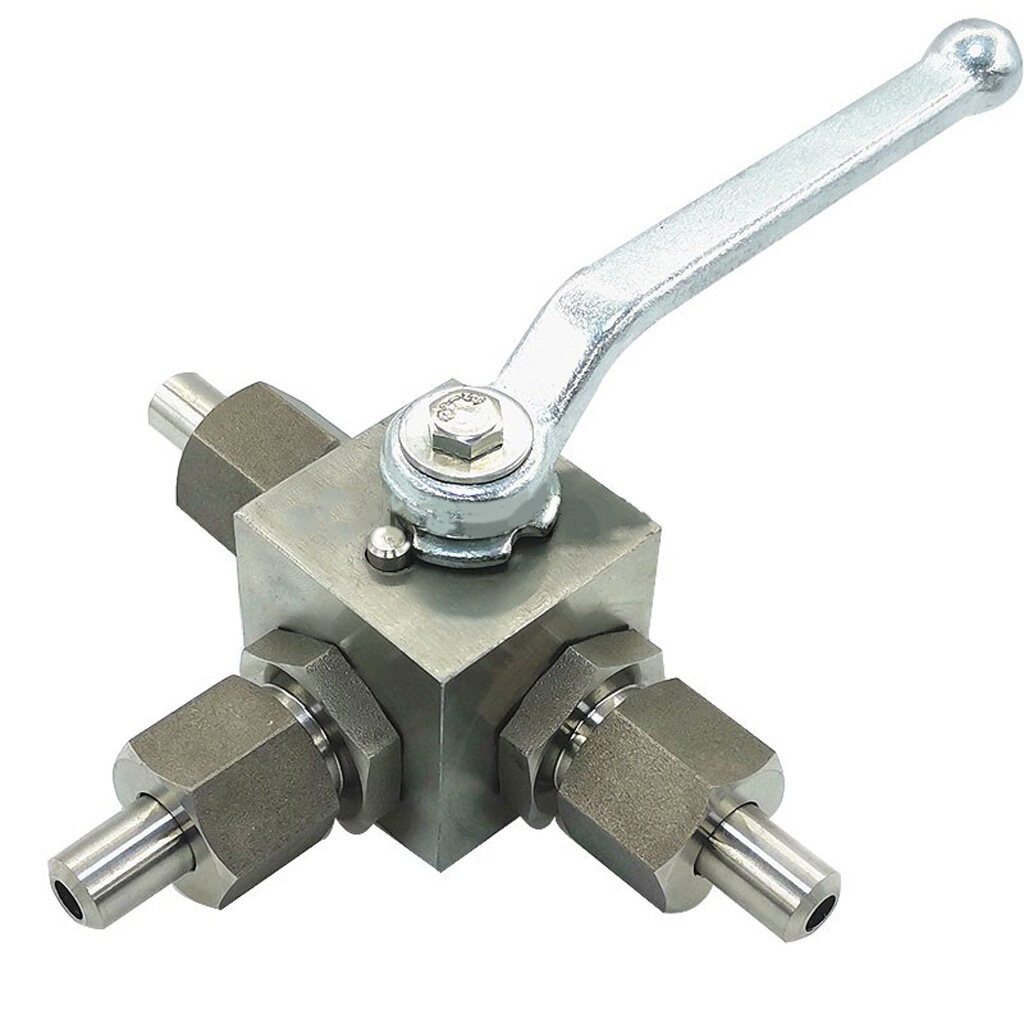

The Essential Guide to 22mm Ball Valves from China

Why the Right Valve Choice Matters

Imagine the frustration of a production line halting due to a single malfunctioning valve. For businesses, this isn't just a minor inconvenience—it's a costly disruption. When it comes to industrial fluid control, every component counts, especially valves that serve as critical gatekeepers for liquids and gases. Among these, the 22mm ball valve is particularly popular due to its compact size and versatile functionality. Whether you're in the food industry, pharmaceuticals, or chemical processing, choosing the right 22mm ball valve can significantly impact your operations. This blog will guide you through the key considerations when sourcing these valves from China, ensuring you make an informed, reliable choice.

What Makes 22mm Ball Valves a Top Choice?

Versatility and Efficiency

Ball valves are designed to provide a secure seal with minimal wear, making them an ideal choice for various applications. The 22mm size is especially favored in systems where space is limited but a robust flow control is required. These valves offer quick shutoff capabilities, which is crucial in emergency situations. Moreover, they can handle a wide range of pressures and temperatures, making them adaptable to diverse industrial needs.

Material Matters: Stainless Steel, Brass, and Beyond

One of the primary factors to consider when selecting a 22mm ball valve is the material. Stainless steel ball valves are renowned for their corrosion resistance and durability, which makes them ideal for harsh environments. On the other hand, brass ball valves are often used in water-related applications due to their cost-effectiveness and reliability. The choice of material not only affects the valve's longevity but also its compatibility with the media it controls.

Sourcing from China: What to Look For

Quality Assurance and Standards

When sourcing 22mm ball valves from China, quality assurance should be your top priority. Reputable manufacturers adhere to stringent quality control processes, ensuring that each valve meets international standards. For instance, many Chinese manufacturers implement a five-step quality control process that includes raw material inspection, high-precision machining, comprehensive bug inspection, ultrasonic cleaning, and final spraying. This meticulous attention to detail guarantees that the valves will perform reliably in critical applications.

Customization and Manufacturing Capabilities

Another significant advantage of sourcing from China is the ability to customize your valves to meet specific needs. Whether you require unique dimensions, specialized coatings, or private labeling, Chinese manufacturers often offer extensive customization options. This flexibility allows you to source a product that perfectly fits your system's requirements, reducing the need for costly modifications down the line.

Navigating the Purchase Process

Understanding Certifications and Compliance

When dealing with Chinese suppliers, it's crucial to verify that the products meet the necessary certifications and industry standards. Look for valves that are certified by organizations such as ISO or CE. These certifications indicate that the products have been tested for safety, quality, and performance. Additionally, understanding the compliance standards specific to your industry will help you avoid purchasing valves that might not be suitable for your applications.

Evaluating Supplier Reputation

Not all suppliers are created equal, so it's important to research the reputation of potential partners. Look for manufacturers with a history of reliability and positive customer reviews. A trustworthy supplier should also offer strong after-sales support, including maintenance guidance and leakage troubleshooting, ensuring a long-lasting relationship.

Applications of 22mm Ball Valve

Some common applications of 22mm ball valves include:

1. Plumbing systems:

Used to control the flow of water in residential and commercial plumbing systems.

2. HVAC systems:

Used to regulate the flow of air and water in heating, ventilation, and air conditioning systems.

3. Industrial processes:

Used in various industrial applications such as chemical processing, oil and gas, and manufacturing.

4. Water treatment plants:

Used to control the flow of water in treatment processes such as filtration, disinfection, and distribution.

5. Irrigation systems:

Used to control the flow of water in agricultural irrigation systems for efficient water distribution.

6. Fire protection systems:

Used to control the flow of water in fire sprinkler systems for fire suppression.

7. Marine and offshore applications:

Used in marine and offshore industries for controlling the flow of fluids in pipelines and systems.

8. Automotive industry:

Used in automotive applications for controlling the flow of fluids in engines, cooling systems, and fuel systems.

Conclusion: Making the Right Choice

Choosing the right 22mm ball valve is more than just selecting a product off the shelf—it's about ensuring that your entire operation runs smoothly and efficiently. By focusing on material quality, manufacturing standards, and supplier reliability, you can make a choice that supports your business's long-term success.

Sourcing from China offers numerous advantages, including customization options and cost-effectiveness, but it's crucial to navigate the process with care. With the right approach, you can find a 22mm ball valve that meets your exact needs and contributes to the seamless operation of your systems.

In conclusion, whether you're upgrading an existing system or setting up a new one, investing in high-quality 22mm ball valves from a reputable Chinese manufacturer will pay dividends in reliability and performance. Take the time to evaluate your options carefully, and you'll be rewarded with a valve that meets your operational demands and exceeds your expectations.