Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Hydraulic Fittings

Hydraulic Fittings

(25)HYDRAULIC FITTINGS

Hydraulic fittings are components used in hydraulic systems to connect hydraulic hoses, tubes, and pipes together, or to connect them to other hydraulic components such as pumps, cylinders, valves, and motors. These fittings play a critical role in ensuring the safe and efficient operation of hydraulic systems.

Hydraulic fittings come in a variety of shapes, sizes, and materials to suit different applications and system requirements. The most common types of hydraulic fittings include:

Adapters: used to connect two different types of fittings or components together.

Couplings: used to connect two hoses or tubes together, or to connect a hose to a machine or other hydraulic component.

Elbows: used to change the direction of the flow of hydraulic fluid.

Tees: used to split the flow of hydraulic fluid into two or more directions.

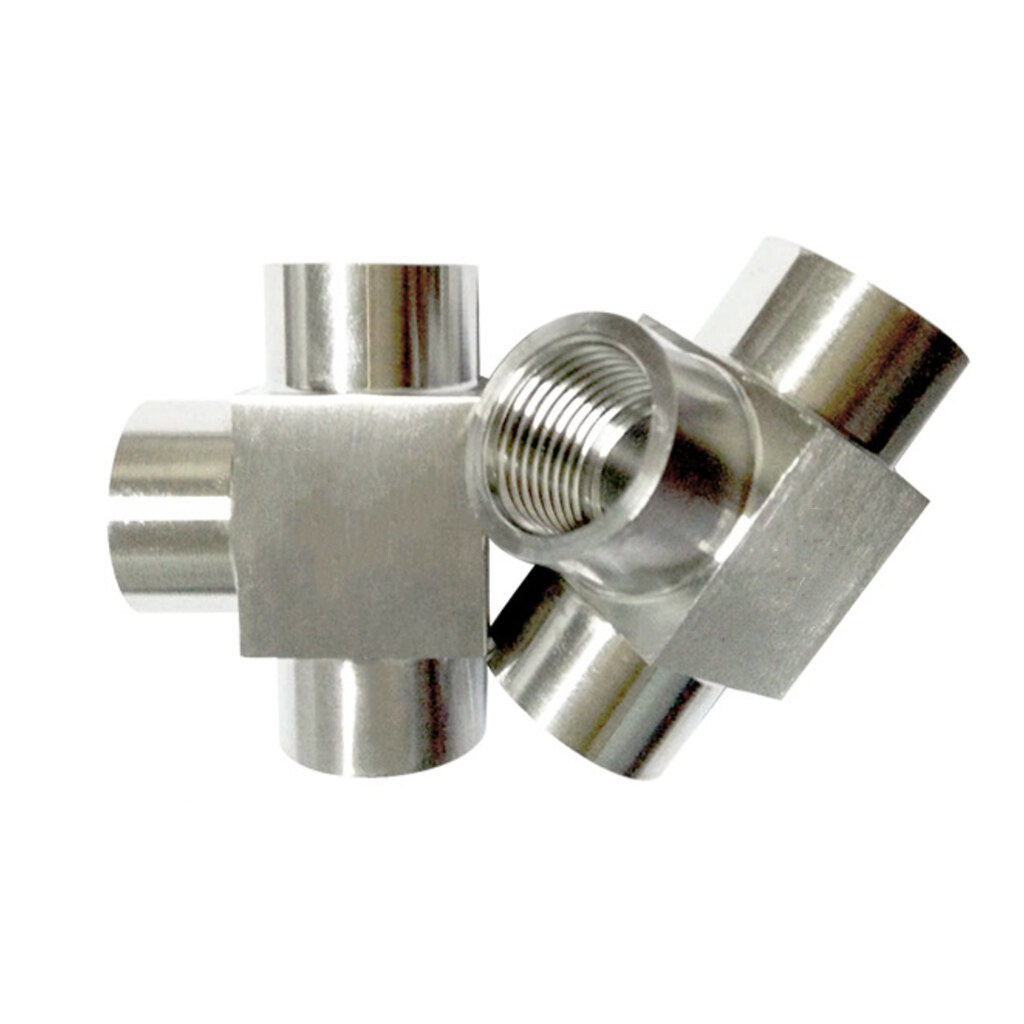

Crosses: used to split the flow of hydraulic fluid into four directions.

Caps and plugs: used to seal off the end of a hose or tube.

Flanges: used to connect two pipes or hoses together.

Hydraulic fittings are typically made of materials such as steel, brass, or stainless steel, and are designed to withstand high pressures and extreme temperatures. It is important to choose the right type of fitting for a particular application, and to ensure that it is installed correctly and maintained regularly to prevent leaks and other problems.

STAINLESS STEEL PIPE FITTING

Stainless steel pipe fittings are used to connect different sections of stainless steel pipes or to connect stainless steel pipes to other types of pipes or equipment. These fittings come in various shapes and sizes, such as elbows, tees, reducers, couplings, and flanges, among others.

Stainless steel is a popular material for pipe fittings because of its excellent corrosion resistance, durability, and strength. It is also easy to clean and maintain, making it suitable for use in a variety of applications, including in the food and beverage, pharmaceutical, chemical, and oil and gas industries.

When selecting stainless steel pipe fittings, it is important to consider factors such as the material grade, temperature and pressure requirements, and the type of fluid or gas being transported. It is also crucial to ensure that the fittings are properly installed and maintained to prevent leaks and ensure optimal performance.

Zcvalve stainless Steel Pipe Fitting Manufacturer/supplier:

Zcvalve is a company that specializes in the design, production, and supply of high-quality stainless steel pipe fittings. They offer a wide range of stainless steel pipe fittings, including elbows, tees, reducers, flanges, and valves, among others.

Zcvalve products are made from high-grade stainless steel materials, which provide excellent resistance to corrosion, high temperature, and pressure. This makes them suitable for use in a wide range of industries, including oil and gas, chemical, food processing, and pharmaceuticals.

zcvalve is known for its commitment to quality, and their products are manufactured in accordance with international standards such as ASTM, ANSI, DIN, and JIS. They also have a team of experienced engineers and technicians who ensure that their products meet the highest standards of quality and reliability.

Overall, if you're looking for a reliable and high-quality supplier of stainless steel pipe fittings, zcvalve is definitely worth considering.

304 Stainless Steel Tee Type High Pressure Fitting Fittings

Tee fittings are typically used at the branch pipes of the main pipe to change the direction of the fluid. can be categorized based on pipe diameter. Three openings, one inlet, two outlets, or two inlets, one outlet, are present on the tee. It is a chemical pipe fitting with equal- and different-diameter nozzles in T and Y shapes. Where two or more pipelines come together, it is used in three places.

Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

Compressed air quick couplings with high performance and safety will increase tool performance and conserve energy. An exhaust disconnect is a feature of the safety fast coupler that prevents kickback and lowers noise levels for safer operation.

Three-way hydraulic compression pipe joint

The component that joins the high-pressure oil pipe and the high-pressure oil pipe in the hydraulic system is known as the hydraulic pipe joint. High pressure ball valves, tube joints, welded pipe joints, high pressure hoses, transition pipe joints, tee pipe joints, non-standard pipe joints, expansion pipe hole type pipe joints, right-angle fittings, swivel fittings, quick connectors, stainless steel fittings, and copper fittings are some of the different types of hydraulic pipe joints.

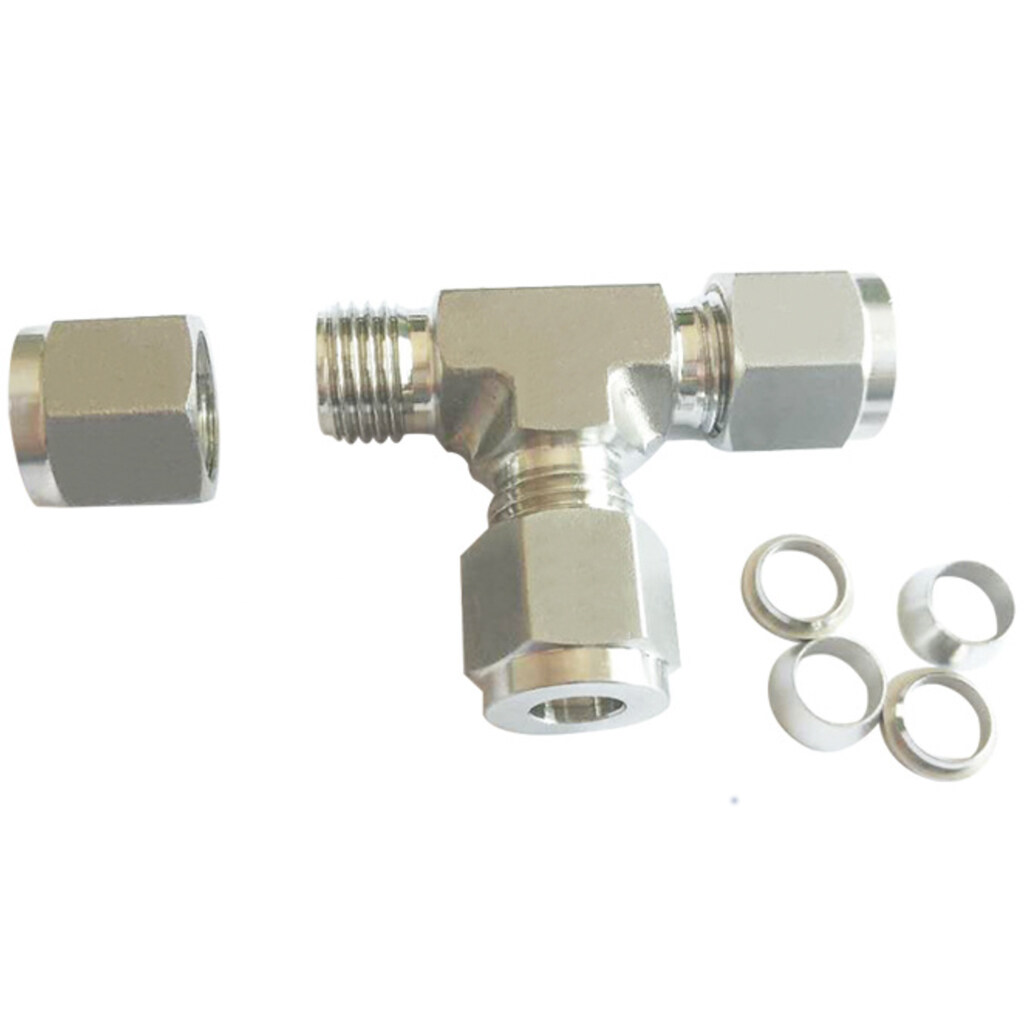

Stainless Steel 304 Compression Fittings with Full Female Tee

Compression fittings, a type of mechanical joint connection fitting used to connect tubing in plumbing systems, are composed of three components. Ferrule, sleeve, compression ring sleeve, compression nut, fitting body (Adapter, Coupling, Elbow, Tee).

Pneumatic Stainless Steel Male Elbow L Type Connector Fittings

The stainless steel hose joint is attractive and has a small overall footprint. It is airtight thanks to its lack of air holes, steel pipes, and box connections. The equipment, box body, steel pipe, hose caliber, and thread are only a few examples of variables that might affect specifications and sizes. The hose (steel pipe) is attached to one end, and the switch box, motor, bridge, etc. are connected to the other end, which is externally threaded.

Pneumatic stainless steel joint hose male thread pneumatic pipe elbow connecting pipe

Male Thread for Pneumatic Stainless Steel Joint Hose All parts, with the exception of the sealing ring, are made of SUS316 stainless steel, which has a high level of corrosion resistance. Pneumatic Pipe Elbow Connecting Pipe is simple and quick to install, and it can be disassembled and recycled.

Card sleeve four-way Valves

The central connection between the steel pipe and the steel pipe is the four-way double ferrule junction. Hexagonal bar is the primary component of the raw material. The nut is silver-plated, and the double ferrule is toughened. High temperatures and pressures are no match for it. It can be used in petroleum, chemical, food, medical, pharmaceutical, ship, hydropower, water supply and drainage, smelting, energy, and other systems. It can also be used on pipes.

ferrule through plate joint

The inner blade of the ferrule through plate joint bites into the seamless steel pipe uniformly to establish an effective seal. There are clamps at both ends of the joint, which are worn on the end of the pipe to be connected and then clamped with a nut. The ferrule joint is extremely practical and does not require welding. It is typically utilized in the center connection of transmission pipes for gas or liquid.

High pressure ferrule joint

The ferrule joint is one of the types of pipe fittings that can be made from a number of materials. These ferrules' primary function is to link or connect several pipe sections. A ferrule junction has a circular clamp that links and connects wires, fibers, or posts. An item is secured with a particular style of ring or cap to prevent cracking, wear, or damage. There are often available ferrule fittings in various diameters. Larger ferrule fittings are constructed in a way that allows their unique hardening procedures to provide improved resistance to leaks and tubes operating at high pressures.

Butt weld head

The thin wall of the pipe, along with the straightforward and practical connecting method, give the stainless steel butt welding head the irreplaceable advantages over other pipe materials in terms of cleanliness, environmental friendliness, cost, and applicability. Stainless steel butt welding heads are being used in a growing number of engineering applications, and people are starting to employ them more frequently. The stainless steel butt welding head is created to meet various connecting needs. The primary way of joining is welding butt welding, and the Geer series joints are utilized for the opposite end.

Butt Weld Terminals

The standard for fluid transmission and general-purpose metal pipe joints, O-ring flat seal joints, is JB/T966. Butt welding terminals are typically used for hydraulic pressure; the pressure is typically quite high in these circumstances.

Butt welding tee

The butt welding tee is a typical pipeline connection type, but most of them have threaded connections as opposed to the butt welding tee's butt welding connection to the steel pipe. for enduring use and stationary pipes The best connectors are butt welds because they rarely leak. Steel pipe piping systems for things like water conservation, electric power, power plants, pipeline fittings, building water supply containers, chemical plants, shipyards, pharmaceutical plants, etc. frequently use butt welding tees.