Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

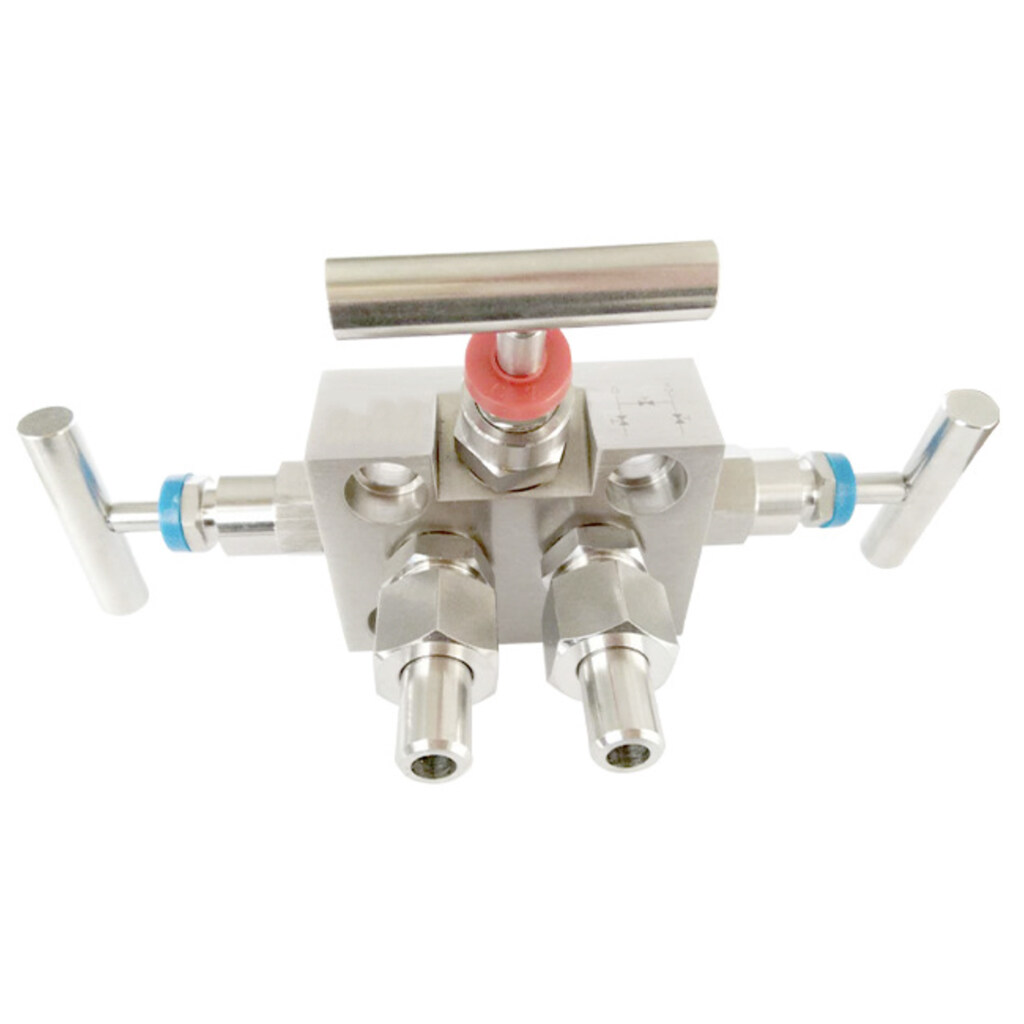

304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves

Needle Valves Made of 304 Stainless Steel syringe valves Globe Valves with Welded External Thread and High Pressure High-quality stainless steel makes up the valve body, and a strong alloy surface serves as the sealing surface. It is a cutting-edge connection valve used in power plants, oil and chemical equipment, and instrument measuring pipelines. It has the advantages of strong sealing performance. The arrow on the valve body should point in the same direction as the medium flow when installing.

304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves

304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves The valve body material is made of high-quality stainless steel and the sealing surface is made of hard alloy surfacing. It has the advantages of good sealing performance and is an advanced connection valve in power station, oil, chemical equipment and instrument measuring pipeline. When installing, the flow direction of the medium should be consistent with the direction of the arrow on the valve body.

The advantages of 304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves

1. The fluid resistance is small, and the sealing surface is less eroded by the medium;

2. Opening and closing is less labor-saving;

3. No disturbance, no pressure reduction;

4. The shape is simple, the structure length is short, the manufacturing process is good, and the application range is wide.

The selection of 304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves

1. For the pipeline system and device of low temperature medium, it is advisable to choose a low temperature needle valve with a valve cover.

2. On the pipeline system of the catalytic cracking unit of the oil refining unit, the lifting rod type needle valve can be selected.

3. In the equipment and pipeline system of corrosive media such as acid and alkali in the chemical system, it is advisable to choose an all-stainless steel needle valve made of austenitic stainless steel and polytetrafluoroethylene as the seat sealing ring.

4. Metal-to-metal sealing needle valves can be selected for pipeline systems or devices of high-temperature media in metallurgical systems, power systems, petrochemical devices, and urban heating systems.

5. When flow regulation is required, a worm gear driven, pneumatic or electric regulating needle valve with V-shaped opening can be selected.

6. For oil and natural gas pipelines that need to be cleaned and buried underground, use full-bore, fully-welded needle valves; if buried on the ground, choose full-bore welded connections or flange connections ball valve.

7. For the transportation pipeline and storage equipment of refined oil, select the needle valve with flange connection.