Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Block Valves

Block Valves

(4)Globe Valve

A globe valve is a type of valve that is commonly used to control the flow of liquids or gases in a pipeline. The valve is named after its spherical shape, which is designed to provide a high level of control over the flow rate and pressure of the fluid passing through it.

The valve consists of a movable disk-shaped element, called the plug, which is held in place by a stationary ring-shaped seat. When the valve is open, the plug is lifted away from the seat, allowing fluid to flow through the valve. When the valve is closed, the plug is pressed down against the seat, preventing fluid from flowing through the valve.

Globe valves are commonly used in applications where precise control over the flow rate and pressure of a fluid is required. They are often used in the oil and gas industry, as well as in chemical and petrochemical plants, power generation facilities, and other industrial applications. Globe valves are available in a variety of sizes, materials, and designs to suit different applications and operating conditions.

Straight Globe Valve

A straight globe valve, also known as a linear globe valve or a Y-pattern globe valve, is a type of globe valve that is designed with a straight flow path through the valve body. In a straight globe valve, the inlet and outlet are aligned in a straight line, which provides a more streamlined flow path for the fluid passing through the valve.

Straight globe valves are often used in applications where low pressure drop and high flow capacity are important considerations. They are commonly used in industries such as HVAC (heating, ventilation, and air conditioning), where they are used to control the flow of water or steam in heating and cooling systems.

The design of a straight globe valve is similar to that of a conventional globe valve, with a movable plug that is held in place by a stationary seat. When the valve is open, the plug is lifted away from the seat, allowing fluid to flow through the valve in a straight line. When the valve is closed, the plug is pressed down against the seat, blocking the flow of fluid.

Straight globe valves are available in a range of sizes, materials, and designs to suit different applications and operating conditions. They can be made from materials such as brass, bronze, cast iron, stainless steel, and carbon steel, and are available with a range of end connections, such as threaded, flanged, and welded.

What is the difference between Globe Valve and straight Globe Valve?

The main difference between a globe valve and a straight globe valve is the flow path through the valve body. In a conventional globe valve, the inlet and outlet are perpendicular to each other, which creates a right-angle turn in the flow path. In contrast, a straight globe valve has a straight flow path, with the inlet and outlet aligned in a straight line.

The straight flow path of a straight globe valve provides a more streamlined flow path for the fluid passing through the valve, which results in lower pressure drop and higher flow capacity compared to a conventional globe valve. This makes straight globe valves a better choice for applications where low pressure drop and high flow capacity are important considerations.

Another difference between the two types of valves is their design. In a conventional globe valve, the valve body and bonnet are typically designed as separate components that are bolted together. In contrast, a straight globe valve has a more compact design, with the valve body and bonnet integrated into a single unit.

Both types of valves have their own advantages and disadvantages, and the choice between them depends on the specific application and operating conditions. While a conventional globe valve may be more appropriate for applications that require precise flow control, a straight globe valve may be a better choice for applications where low pressure drop and high flow capacity are important considerations.

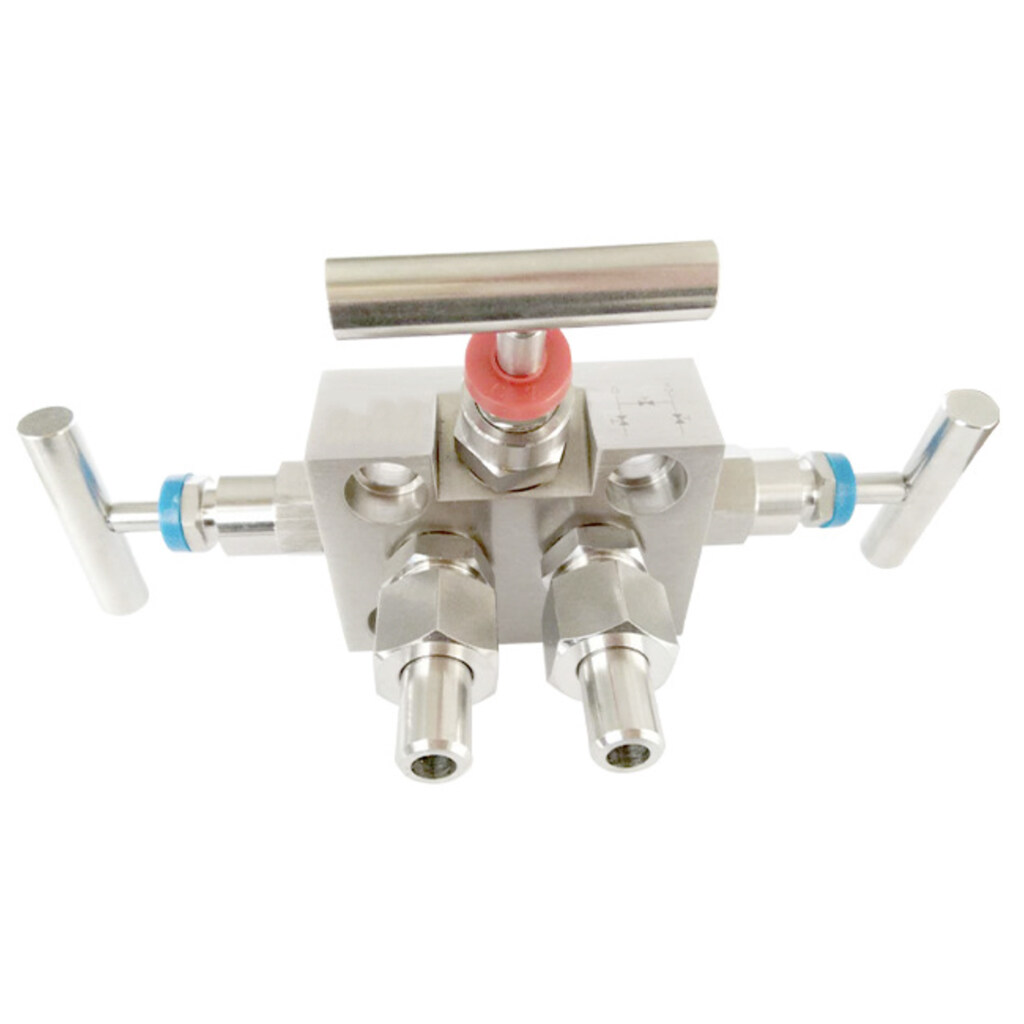

Stainless Steel Instrumentation Three-Valves Manifold Pressure Transmitter Accessories

Three-Valves Manifold Pressure Transmitter Accessories made of stainless steel are frequently used in automatic control systems in the chemical, metallurgical, textile, petroleum, and electrical power industries. The three-valve group uses a non-rotating valve stem, a working thread that does not come into contact with the system medium, and a forged valve body that was created using foreign product technology. It is of excellent quality, has a lovely appearance, and an exceptional shape. It is the perfect transmitter for differential pressure. supplementary goods

Internal thread mini stainless steel ball Valves globe Valves

Mini Stainless Steel Ball Valves with Internal Thread Manual valves include globe valves. The ball valve is a type of valve that achieves opening and closing by rotating a sphere with a circular tube that serves as the opening and closing component. The ball valve's opening and closing mechanism consists of a ball with a hole that rotates around an axis perpendicular to the channel to open and close the channel.

304 Stainless Steel Needle Valves Needle Valves Welded External Thread High Pressure Globe Valves

Needle Valves Made of 304 Stainless Steel syringe valves Globe Valves with Welded External Thread and High Pressure High-quality stainless steel makes up the valve body, and a strong alloy surface serves as the sealing surface. It is a cutting-edge connection valve used in power plants, oil and chemical equipment, and instrument measuring pipelines. It has the advantages of strong sealing performance. The arrow on the valve body should point in the same direction as the medium flow when installing.

Stainless Steel High Pressure Compression End Connection Double Ferrule Valves Bellows Sealed Globe Valves

High Pressure Compression End Connection in Stainless Steel Bellows with Double Ferrule Valves Disc, spring, central shaft, and valve body make up sealed globe valves. The materials are all high-quality stainless steel, with the exception of the valve body, which is constructed of high-quality carbon steel. In order to stop the medium from flowing backward, it depends on the medium's flow to automatically open and close the disc. There are several other names for it, including check valve, one-way valve, reverse flow valve, and back pressure valve.