Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Valves

Valves

(22)A high pressure safety valve is a type of safety valve designed to protect pressure vessels or piping systems from overpressure. These valves are typically used in industries such as oil and gas, petrochemicals, power generation, and process manufacturing, where the release of pressure could result in serious harm to people, the environment, or equipment.

High pressure safety valves are designed to automatically open when the pressure inside the vessel or piping system exceeds a predetermined level, called the set point. When this happens, the valve will release a controlled amount of fluid or gas, which reduces the pressure inside the system and prevents it from reaching dangerous levels.

It's important to note that high pressure safety valves must be properly selected and sized based on the specific application and the fluid or gas being processed. They must also be installed and maintained according to strict guidelines and regulations to ensure their reliability and effectiveness.

High Pressure Safety Valve Manufacturer/supplier

ZCVALVE is a Chinese company that specializes in the manufacturing and supply of industrial valves, including high pressure safety valves. They offer a wide range of products to meet the needs of various industries, including oil and gas, petrochemicals, and power generation. ZCVALVE's high pressure safety valves are designed to comply with international standards and are known for their reliability, durability, and performance.

When choosing a high pressure safety valve manufacturer or supplier, it's important to consider factors such as the company's reputation, experience, quality of products, and customer service. It's also essential to ensure that the manufacturer/supplier complies with applicable safety and regulatory standards, such as ASME, API, and ISO.

There are many reputable manufacturers and suppliers of high pressure safety valves worldwide, and it's important to do your research and choose a supplier that meets your specific needs and requirements.

Card sleeve three-way ball Valves

Card Sleeve Three-Way Ball Valves use a top entry ball valve that is made of an overall bar material. ball valve with a smaller diameter.

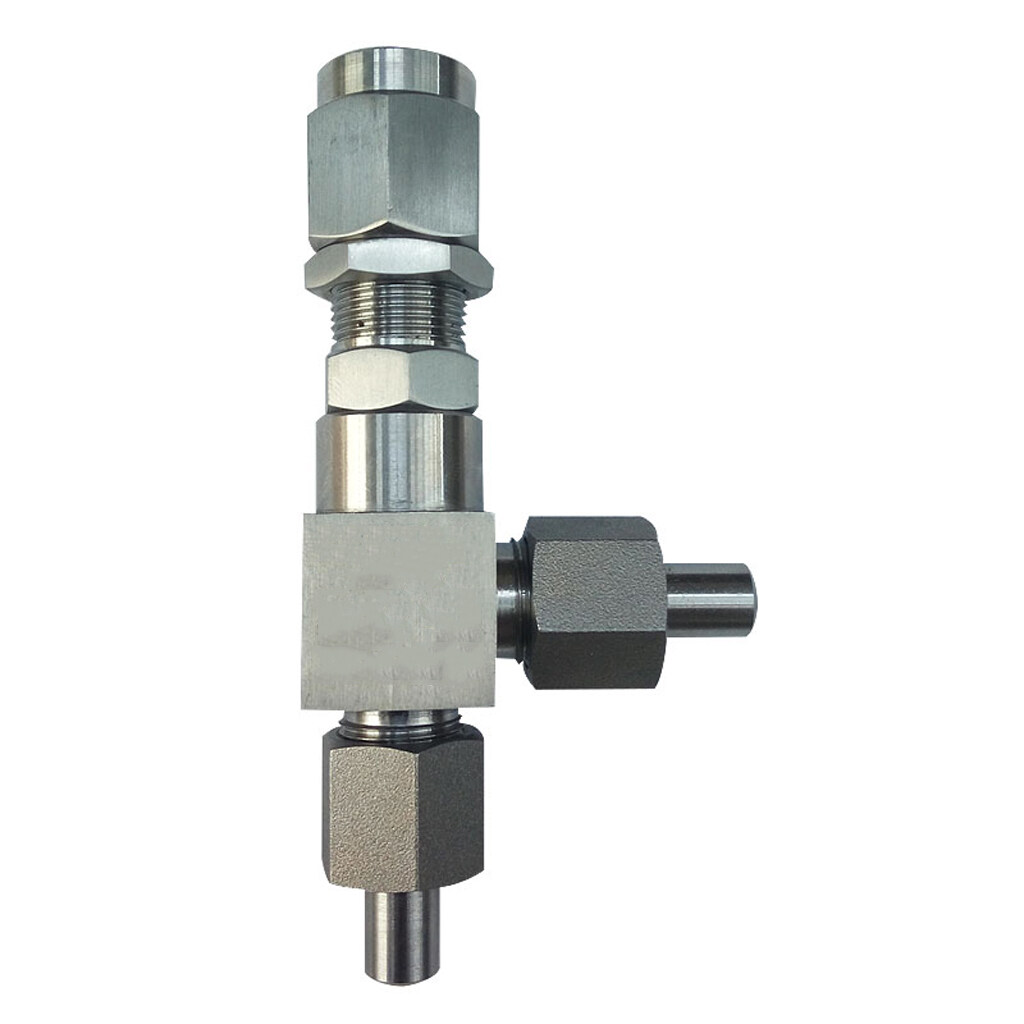

Stainless Steel High Pressure Compression End Connection Double Ferrule Valves Bellows Sealed Globe Valves

High Pressure Compression End Connection in Stainless Steel Bellows with Double Ferrule Valves Disc, spring, central shaft, and valve body make up sealed globe valves. The materials are all high-quality stainless steel, with the exception of the valve body, which is constructed of high-quality carbon steel. In order to stop the medium from flowing backward, it depends on the medium's flow to automatically open and close the disc. There are several other names for it, including check valve, one-way valve, reverse flow valve, and back pressure valve.

Male to Female Stainless Steel 304 Adjustable Needle Valves

Male to Female Stainless Steel 304 Adjustable Needle Valves are typically used for sealing gas or liquid media with little flow and high pressure (such as steam, oil). These valves have good sealing performance. The internal thread needle globe valve has a long service life and good sealing performance. Only by replacing the wearing elements can it be used even if the sealing surface is broken. It serves as a connecting valve in power plants, oil refineries, chemical plants, and pipelines used for instrument measurement.

single Valves

Due to the single valve, fluid can only travel via the water inlet and cannot flow back through the outflow medium. Single valves may also be referred to as check valves. used in pneumatic systems to stop the flow of compressed air backwards or in hydraulic systems to stop the flow of oil backwards.

SS316 Stainless Steel Double Ferrule One-Piece Bonnet Needle Valves

The Ss316 Stainless Steel Double Ferrule One-Piece Bonnet Needle Valves get its name from the extremely pointed cone-shaped valve core that is fitted into the valve seat like a needle. Needle valves are typically used for sealing gas or liquid media with lesser flow rates and higher pressures because they have better sealing performance and can sustain greater pressure than other types of valves. The best application for needle valves is with pressure gauges. Needles valves are typically formed into flanges, threaded connections, and other types of connections.

Stainless Steel High Pressure Butt Welded Ball Valves

In thermal power plants, high-pressure butt welding ball valves are typically employed on pipelines of various systems to join or disconnect pipeline media. Non-corrosive media, such as water and steam, is the applicable medium. The high pressure butt welding ball valve stands out from other ball valve products because to its distinctive self-sealing construction; the greater the pressure, the more reliable the seal. The product has developed qualities due to the unique technical, performance, and working conditions that cannot be substituted by other items.

Stainless steel high pressure relief Valves

When pressures must be swiftly released to prevent harm from system overpressure, utilize these valves for emergency relief. When the overpressure needs to be controlled more gradually, such as in back pressure or pump bypass applications, use our back-pressure/bypass valves. When relief valves are selected for pressure control applications, this will reduce the possibility of pressure spikes, which frequently occur.

Sleeve spring type safety relief Valves

Safety Relief of the Sleeve Spring Type In order to balance the force acting on the disc, valves utilise the force of the compression spring. By rotating the adjustment nut on the helical coil spring, the amount of compression can be changed. With this arrangement, the safety valve's opening (set) pressure can be adjusted as necessary.

Stainless steel SS316 double tube joint fine-tuning Valves micro-regulating Valves metering control Valves

The stainless steel fine-tuning valve's features include high precision, small size, dependable operation, and effective sealing. Its structural design is reasonable, and it has a lovely look. It is employed in the vacuum system to modify the degree of vacuum and gas flow. Turning the adjusting knob by hand moves the high-vacuum manual fine-tuning valve into action, and thread transmission moves the valve needle up and down. The valve's medium can be either air or a small quantity of corrosive gas.

Stainless Steel Welded Globe Needle Valves

The name "Stainless Steel Welded Globe Needle Valves" refers to the mechanism of the valve's small, tapered plug and port. The needle valve's tiny size allows for fine fluid flow control. When pressure or flow needs to be safely lowered or controlled, needle valves are utilized.

Internal thread stainless steel micro-control metering needle Valves

Internal Thread Stainless Steel Micro-Control Metering Needle Valves have a 32 MPA pressure resistance rating, making them suitable for use in gas pipelines. They also have a high flow regulation accuracy, lovely appearance, and a good texture, making them primarily used in laboratories, chemical pipelines, and other gas regulation.

Stainless Steel Needle Valves

The purpose of the stainless steel needle valve, which consists of a globe valve and a ball valve, is to measure the pressure of the liquid in the pipeline as well as the flow's speed and pressure. The stainless steel needle valve, a type of valve device positioned horizontally, is typically installed in the pipeline and has a respectably accurate measuring effect.