Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Needle Valves

Needle Valves

(9)A high pressure needle valve is a specific type of needle valve that is designed to operate at higher pressure levels than standard needle valves. These valves are typically made from durable, high-strength materials such as stainless steel or alloy steel, and are designed to withstand the high pressures and temperatures that are often encountered in industrial applications.

It is designed with a tapered needle-shaped plunger that is inserted into a conical valve seat. As the plunger is turned or adjusted, the opening between the needle and the seat can be varied to control the flow of fluid through the valve.

Needle valves are commonly used in applications where precise control of flow rates is required, such as in laboratory equipment, chemical processing, and hydraulic systems. They can be made from a variety of materials, including brass, stainless steel, and plastic, and are available in a range of sizes and pressure ratings.

High pressure needle valves are commonly used in applications such as oil and gas production, chemical processing, and power generation. They are often used to control the flow of high-pressure fluids, gases, or steam in pipes, tanks, or other vessels.

One key feature of high pressure needle valves is their ability to provide precise flow control even at very high pressures. They are often designed with a finer taper than standard needle valves, which allows for more precise adjustments and better control over the flow rate.

High pressure needle valves are an important component in many industrial processes, providing reliable and accurate control over the flow of high-pressure fluids and gases.

ZC Valve - China Needle Valve Manufacturer

ZC Valve is a company that manufactures a wide range of industrial valves, including needle valves, ball valves, check valves, and gate valves. Their needle valves are designed to provide precise flow control in a variety of industrial applications, and are available in a range of materials, sizes, and pressure ratings.

In addition to their standard needle valve products, ZC Valve also offers custom valve design and manufacturing services, allowing them to provide tailored solutions to meet specific customer needs. They also offer a range of testing and certification services, ensuring that their valves meet the highest quality and safety standards.

ZC Valve is a reliable and reputable manufacturer of needle valves and other industrial valves, with a focus on quality, performance, and customer satisfaction.

External thread stainless steel micro-control metering needle Valves

External Thread Stainless Steel Micro-Control Metering Needle Valves are made of whole body stainless steel, resistant to high pressure, high temperature, and corrosion; beautiful in appearance, compact in structure, special elongated valve tip, and knob with scale, truly achieve the purpose of precise micro-adjustment. Mainly used in: scientific research, laboratory, chemical industry, pharmaceutical and other fields.

SS316 Stainless Steel Corrosion Resistant Male Thread Straight Needle Valves

Needle globe valves and needle ball valves, which are used to open or close pipeline access, are two types of Ss316 stainless steel corrosion-resistant male thread straight needle valves that are a crucial component of the instrument measurement pipeline system. The needle valve gets its name from the fact that its spool, an extremely pointed cone, is put into the valve seat in the shape of a needle. Although their nominal diameters are small, needle valves can be employed in high-pressure, high-temperature pipeline conditions.

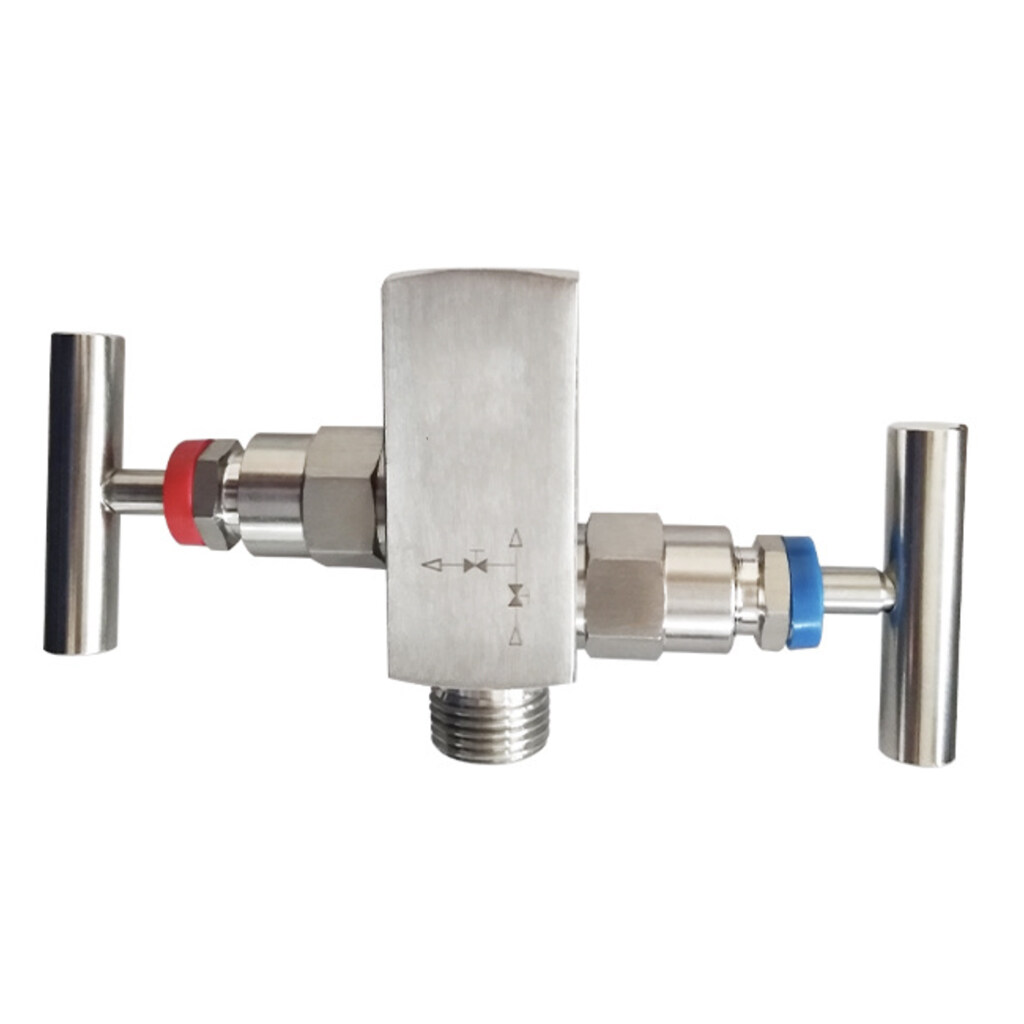

Instrumentation Needle Valves Stainless Steel SS304 SS316 Manifold Valves

Instrumentation Needle Valves Stainless Steel Ss304 Ss316 Manifold Valves are used to measure liquid level and interface in containers as well as the flow rate, differential pressure, and gauge pressure of different liquids, gases, and steam in pipelines. In the chemical industry, metallurgy, electric power, textile, food, and other industries, the manifold valve is frequently employed.

Male to Female Stainless Steel 304 Adjustable Needle Valves

Male to Female Stainless Steel 304 Adjustable Needle Valves are typically used for sealing gas or liquid media with little flow and high pressure (such as steam, oil). These valves have good sealing performance. The internal thread needle globe valve has a long service life and good sealing performance. Only by replacing the wearing elements can it be used even if the sealing surface is broken. It serves as a connecting valve in power plants, oil refineries, chemical plants, and pipelines used for instrument measurement.

SS316 Stainless Steel Double Ferrule One-Piece Bonnet Needle Valves

The Ss316 Stainless Steel Double Ferrule One-Piece Bonnet Needle Valves get its name from the extremely pointed cone-shaped valve core that is fitted into the valve seat like a needle. Needle valves are typically used for sealing gas or liquid media with lesser flow rates and higher pressures because they have better sealing performance and can sustain greater pressure than other types of valves. The best application for needle valves is with pressure gauges. Needles valves are typically formed into flanges, threaded connections, and other types of connections.

Stainless Steel Welded Globe Needle Valves

The name "Stainless Steel Welded Globe Needle Valves" refers to the mechanism of the valve's small, tapered plug and port. The needle valve's tiny size allows for fine fluid flow control. When pressure or flow needs to be safely lowered or controlled, needle valves are utilized.

Internal thread stainless steel micro-control metering needle Valves

Internal Thread Stainless Steel Micro-Control Metering Needle Valves have a 32 MPA pressure resistance rating, making them suitable for use in gas pipelines. They also have a high flow regulation accuracy, lovely appearance, and a good texture, making them primarily used in laboratories, chemical pipelines, and other gas regulation.

Stainless Steel Needle Valves

The purpose of the stainless steel needle valve, which consists of a globe valve and a ball valve, is to measure the pressure of the liquid in the pipeline as well as the flow's speed and pressure. The stainless steel needle valve, a type of valve device positioned horizontally, is typically installed in the pipeline and has a respectably accurate measuring effect.