Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

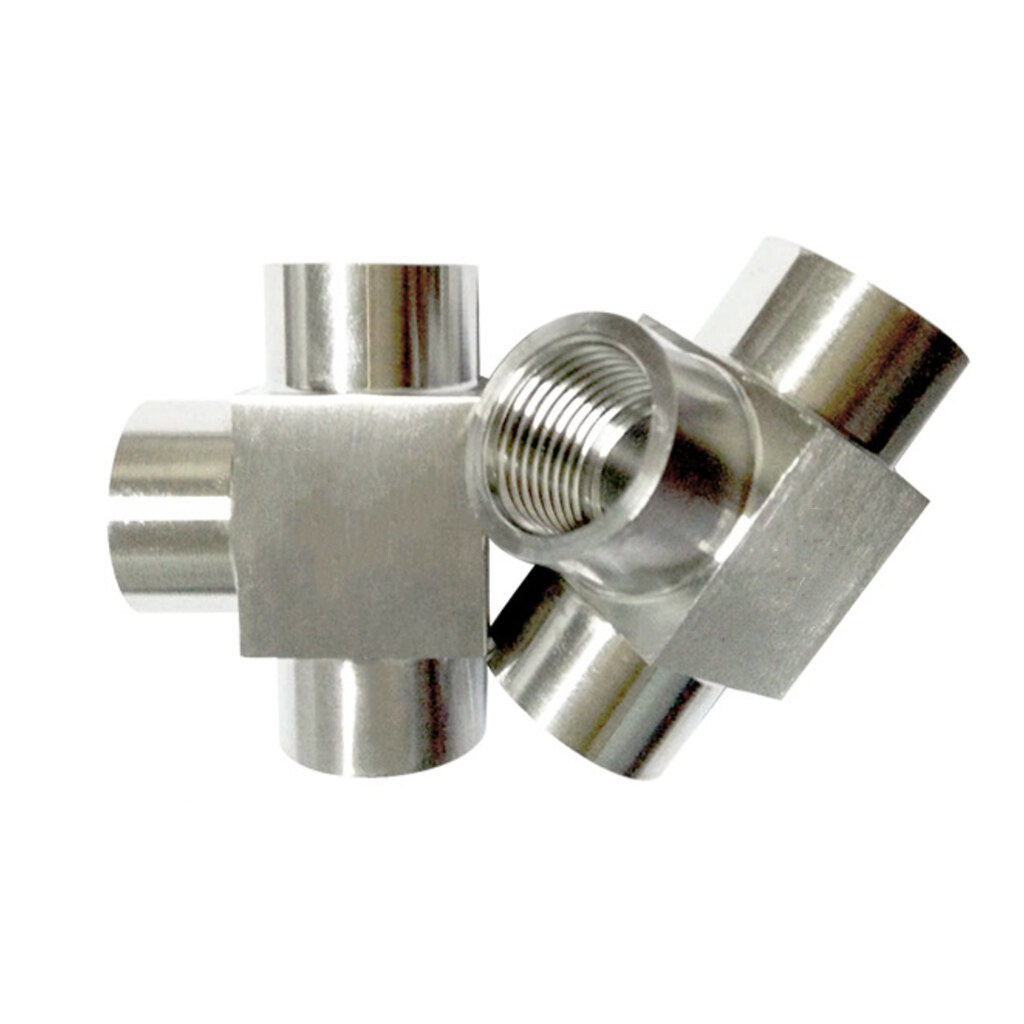

Stainless Steel Fittings

Stainless Steel Fittings

(18)Stainless steel fittings are components used to connect and join stainless steel pipes and tubing in various applications. Stainless steel fittings are known for their durability, corrosion resistance, and strength, which makes them ideal for use in harsh and corrosive environments.

Stainless steel fittings come in various types, sizes, and grades to suit different applications. Some common types of stainless steel fittings include:

Stainless Steel Compression Fittings: These fittings use a compression nut and ferrule to create a tight seal between the fitting and the pipe or tubing. They are commonly used in high-pressure applications and where vibration or movement is a concern.

Stainless Steel Threaded Fittings: These fittings have male or female threads that allow them to be screwed into other components, such as valves or pipes. They are commonly used in plumbing and industrial applications.

Stainless Steel Butt Weld Fittings: These fittings are welded to the pipe or tubing, creating a permanent and leak-proof connection. They are commonly used in high-pressure and high-temperature applications.

Stainless Steel Flanges: These fittings are used to connect two pipes or tubes together, or to connect a pipe or tube to a valve or other component. They are commonly used in industrial applications where high pressure and temperature are a concern.

Stainless steel fittings are typically made from austenitic stainless steel, which contains chromium and nickel, making them resistant to corrosion and staining. The grade of stainless steel used in the fittings can affect their performance in different environments. For example, 316 stainless steel is commonly used in marine environments due to its higher resistance to corrosion from saltwater.

Stainless Steel Fittings Manufacturer/factory In China - ZCVALVE

ZCVALVE is a manufacturer of stainless steel fittings that are designed for use in various applications in the petrochemical, pharmaceutical, and food processing industries, among others. They offer a wide range of stainless steel fittings, including valves, flanges, and pipe fittings, all made from high-quality materials and manufactured to international standards.

ZCVALVE stainless steel fittings are made from high-quality materials, including 304 and 316 stainless steel, which makes them durable and resistant to corrosion. Their fittings are also designed to meet international standards such as ANSI, ASTM, and DIN, ensuring that they are suitable for use in a wide range of applications.

Some of the types of stainless steel fittings manufactured by ZCVALVE include:

Stainless Steel Ball Valves: These valves are designed for use in various applications, including the oil and gas industry, food processing, and pharmaceuticals. They come in different sizes, materials, and designs to meet specific customer needs.

Stainless Steel Flanges: These fittings are used to connect pipes or tubes together, or to connect pipes to other components. ZCVALVE manufactures flanges in different sizes, materials, and classes, including ANSI, DIN, and JIS.

Stainless Steel Pipe Fittings: These fittings are used to connect pipes or tubes together or to change the direction of flow in a piping system. ZCVALVE manufactures pipe fittings in different sizes, materials, and configurations, including elbows, tees, reducers, and couplings.

ZCVALVE is a reputable manufacturer of stainless steel fittings that are designed for use in various industries. Their fittings are made from high-quality materials, manufactured to international standards, and come in different sizes, materials, and configurations to meet specific customer needs.

Pneumatic stainless steel joint hose male thread pneumatic pipe elbow connecting pipe

Male Thread for Pneumatic Stainless Steel Joint Hose All parts, with the exception of the sealing ring, are made of SUS316 stainless steel, which has a high level of corrosion resistance. Pneumatic Pipe Elbow Connecting Pipe is simple and quick to install, and it can be disassembled and recycled.

Stainless Steel Fitting Flange Adapter - 45 Degree Metric Male Thread and 24 Degree Female Cone

The stainless steel fitting flange adapter with a 45 degree metric male thread and 24 degree female cones was made in accordance with SAE J514 and ISO 8434-2 standards. A complete set of Stainless Steel Fitting Flange Adapter - 45 Degree Metric Male Thread And 24 Degree Female Cones consists of a sleeve, nut, and body. They are sometimes known to as flared fittings because of the 37-degree flare of the seating surface. It is advised to use it in high-pressure applications.

Butt welding tee

The butt welding tee is a typical pipeline connection type, but most of them have threaded connections as opposed to the butt welding tee's butt welding connection to the steel pipe. for enduring use and stationary pipes The best connectors are butt welds because they rarely leak. Steel pipe piping systems for things like water conservation, electric power, power plants, pipeline fittings, building water supply containers, chemical plants, shipyards, pharmaceutical plants, etc. frequently use butt welding tees.

Card sleeve four-way Valves

The central connection between the steel pipe and the steel pipe is the four-way double ferrule junction. Hexagonal bar is the primary component of the raw material. The nut is silver-plated, and the double ferrule is toughened. High temperatures and pressures are no match for it. It can be used in petroleum, chemical, food, medical, pharmaceutical, ship, hydropower, water supply and drainage, smelting, energy, and other systems. It can also be used on pipes.

Stainless Steel 304 Compression Fittings with Full Female Tee

Compression fittings, a type of mechanical joint connection fitting used to connect tubing in plumbing systems, are composed of three components. Ferrule, sleeve, compression ring sleeve, compression nut, fitting body (Adapter, Coupling, Elbow, Tee).

High pressure ferrule joint

The ferrule joint is one of the types of pipe fittings that can be made from a number of materials. These ferrules' primary function is to link or connect several pipe sections. A ferrule junction has a circular clamp that links and connects wires, fibers, or posts. An item is secured with a particular style of ring or cap to prevent cracking, wear, or damage. There are often available ferrule fittings in various diameters. Larger ferrule fittings are constructed in a way that allows their unique hardening procedures to provide improved resistance to leaks and tubes operating at high pressures.

ferrule through plate joint

The inner blade of the ferrule through plate joint bites into the seamless steel pipe uniformly to establish an effective seal. There are clamps at both ends of the joint, which are worn on the end of the pipe to be connected and then clamped with a nut. The ferrule joint is extremely practical and does not require welding. It is typically utilized in the center connection of transmission pipes for gas or liquid.

Check Valves for Air Suspension Lowrider Universal Air Compressor

A check valve, also referred to as a one-way valve, is one type of valve that only allows air to flow in one direction. Check valves are placed at the end of compressor leader lines and are useful for keeping your air tank separate from your bags. In order to remove the air tank while still maintaining air pressure in the air springs, many individuals install a check valve between their air tank and manifold. This also gives comfort in knowing that the air springs won't progressively lose inflated due to a tank leak.

Stainless Steel Double Ferrule Elbow Fitting Elbow Fitting

The steel pipe is inserted into the ferrule, secured with the ferrule nut, brought in contact with the ferrule, and then the pipe is cut into and sealed. When it is connected to the steel pipe, it does not need to be welded, which is advantageous for high-altitude operation, fire prevention, and explosion prevention. It can also eliminate the drawbacks brought on by accidental welding.

Butt Weld Terminals

The standard for fluid transmission and general-purpose metal pipe joints, O-ring flat seal joints, is JB/T966. Butt welding terminals are typically used for hydraulic pressure; the pressure is typically quite high in these circumstances.

304 Stainless Steel Tee Type High Pressure Fitting Fittings

Tee fittings are typically used at the branch pipes of the main pipe to change the direction of the fluid. can be categorized based on pipe diameter. Three openings, one inlet, two outlets, or two inlets, one outlet, are present on the tee. It is a chemical pipe fitting with equal- and different-diameter nozzles in T and Y shapes. Where two or more pipelines come together, it is used in three places.

Stainless steel ferrule five-way ball Valves

A spherical valve core is utilized, together with a spherical sealing ring, to ensure the sealing performance between the valve body and the valve core in the stainless steel five-way ball valve. To guarantee the tightness of the connection between the valve core and the valve sleeve, the valve core and the valve sleeve must be connected via a compression spring.