Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

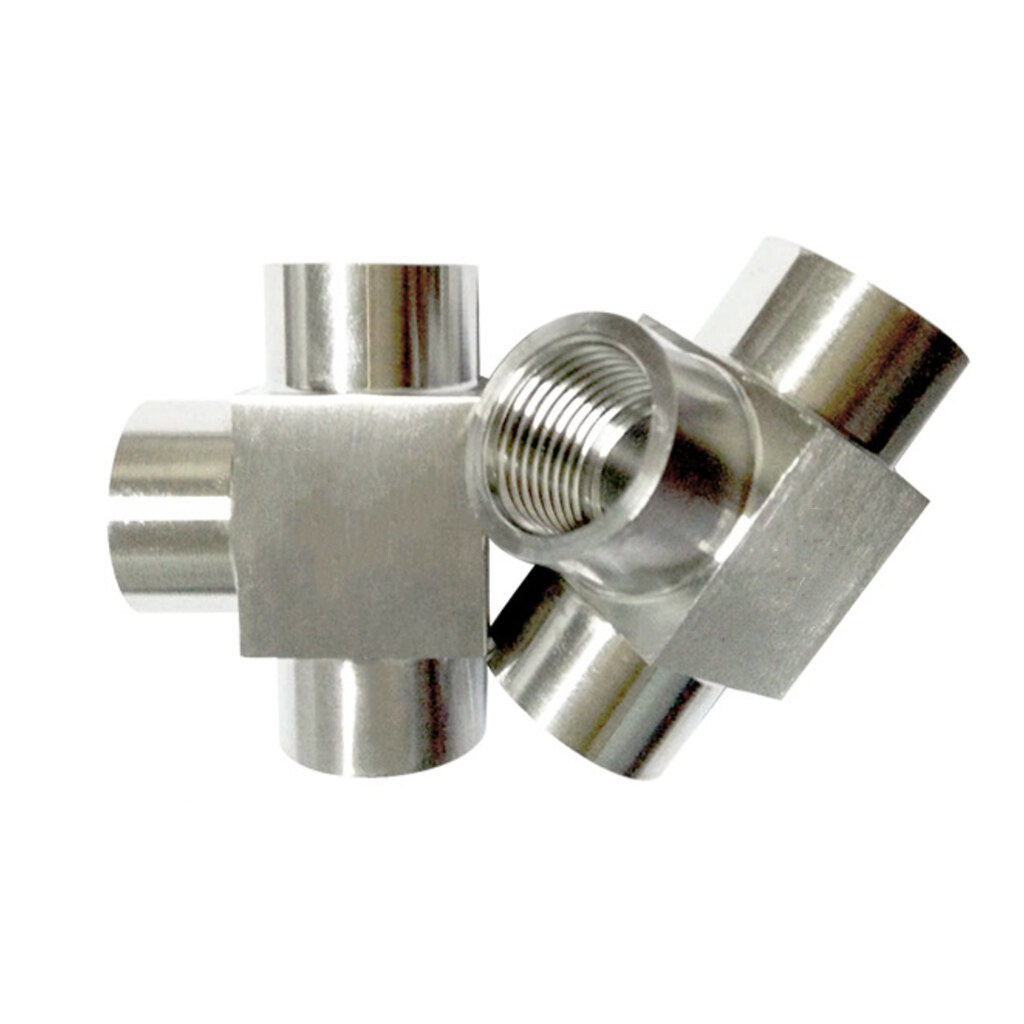

304 Stainless Steel Tee Type High Pressure Fitting Fittings

Tee fittings are typically used at the branch pipes of the main pipe to change the direction of the fluid. can be categorized based on pipe diameter. Three openings, one inlet, two outlets, or two inlets, one outlet, are present on the tee. It is a chemical pipe fitting with equal- and different-diameter nozzles in T and Y shapes. Where two or more pipelines come together, it is used in three places.

304 Stainless Steel Tee Type High Pressure Fitting Fittings

Tee fittings are mainly used to change the direction of the fluid and are used at the branch pipes of the main pipe. Can be classified according to pipe diameter. The tee has three openings, that is, one inlet and two outlets; or two inlets and one outlet. It is a chemical pipe fitting with T-shaped and Y-shaped, equal-diameter nozzles and different-diameter nozzles. It is used for three Where the same or different pipelines meet.

The craftsmanship of 304 Stainless Steel Tee Type High Pressure Fitting Fittings

The forming of the tee joint is to flatten the tube blank larger than the diameter of the tee to the size of the tee diameter, and open a hole at the part of the stretched branch pipe; the tube blank is heated, put into the forming mold, and installed in the tube blank Under the action of pressure, the tube blank is radially compressed, and during the radial compression process, the metal flows in the direction of the branch pipe and forms a branch pipe under the stretching of the die. The whole process is formed by the radial compression of the tube blank and the stretching process of the branch pipe. Different from the hydraulic bulging tee, the metal of the branch pipe of the tee joint is compensated by the radial movement of the tube blank, so it is also called the radial compensation process.

Due to the use of heated and pressed tees, the tonnage of equipment required for material forming is reduced. The hot-pressed tee has a wide adaptability to materials, and is suitable for low-carbon steel, alloy steel, and stainless steel; especially for tees with large diameters and thick pipe walls, this forming process is usually used.