Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

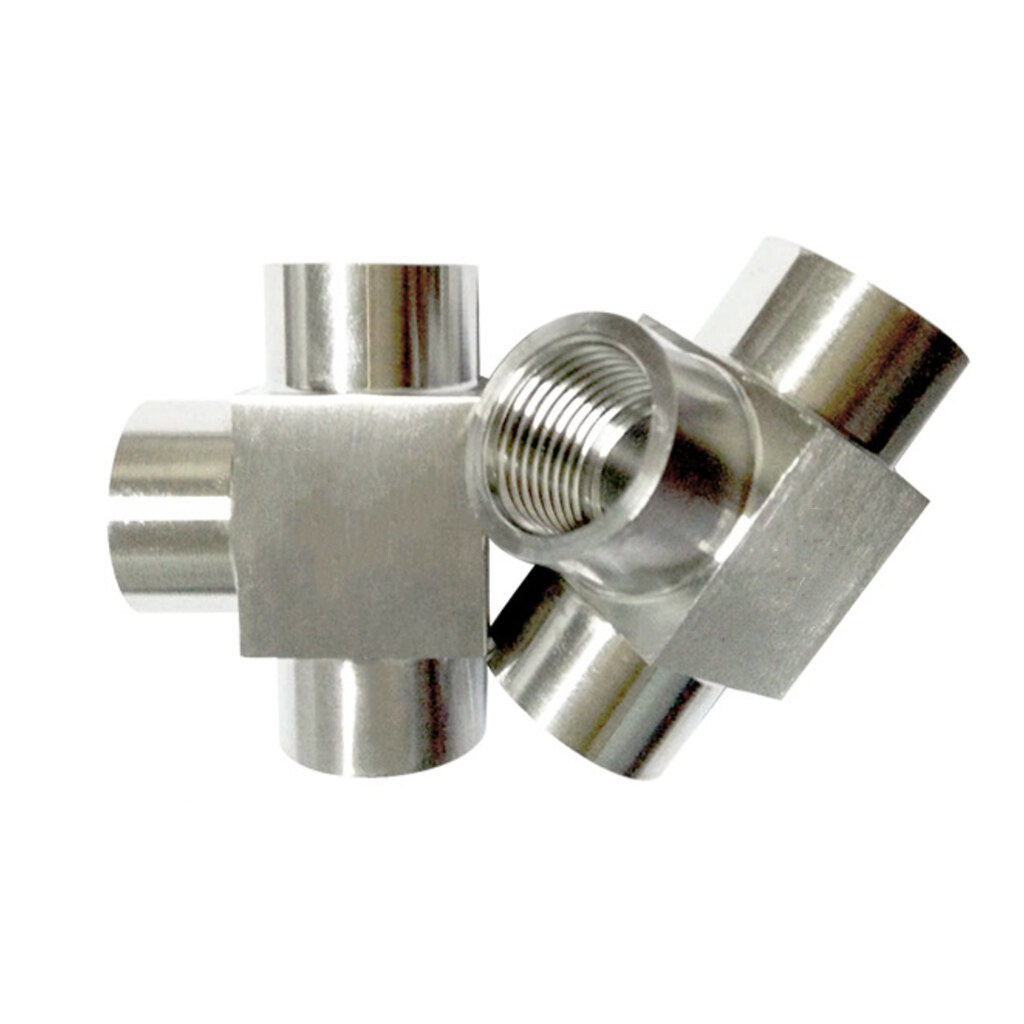

Butt Weld Terminals

The standard for fluid transmission and general-purpose metal pipe joints, O-ring flat seal joints, is JB/T966. Butt welding terminals are typically used for hydraulic pressure; the pressure is typically quite high in these circumstances.

Butt Weld Terminals

Butt welding terminals are generally used for hydraulic pressure, the standard is JB/T966 for fluid transmission and general purpose metal pipe joints, O-ring flat seal joints, this standard joint is generally used for hydraulic pressure, and the pressure is relatively high occasion.

The features of Butt Weld Terminals

Corrosion resistance, high pressure resistance, high temperature resistance, durable, good sealing performance

The use of Butt Weld Terminals

Used in electric power, mechanical and electrical engineering, chemical engineering, petrochemical, gas source pneumatic, hydraulic pipeline, chemical papermaking, machinery manufacturing, shipbuilding, metallurgy, aerospace and other pipelines.

The installation of Butt Weld Terminals

1. First, the inside and outside of the connected stainless steel pipe fittings should be sorted out before connecting the butt welding flange.

2. Then connect the flange holes with bolts, and the bolt components need to be tightened symmetrically.

3. Embed the O-shaped rubber sealing ring and stainless steel sealing ring installed on both sides in the flange with grooved ring. The inner hole of the sealing ring is the same as the inner diameter of the pipe.

4. When tightening the butt welding flange, pay attention to make the tightness of each joint outstanding, and all of them must meet the required specifications.

5. Install the flanges with grooved rings on the pipes that need to be connected.

6. The port of the pipe needs to be processed by 90-degree flanging process. After the treatment, the port plane of the pipe needs to be polished. After grinding, it should be vertical and flat, and there are no problems of burrs, unevenness and deformation, and the pipe port needs to be rounded with tools.

7. Another simple method is to use the finished product to flang the short pipe and then weld it on the pipe for use.