Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

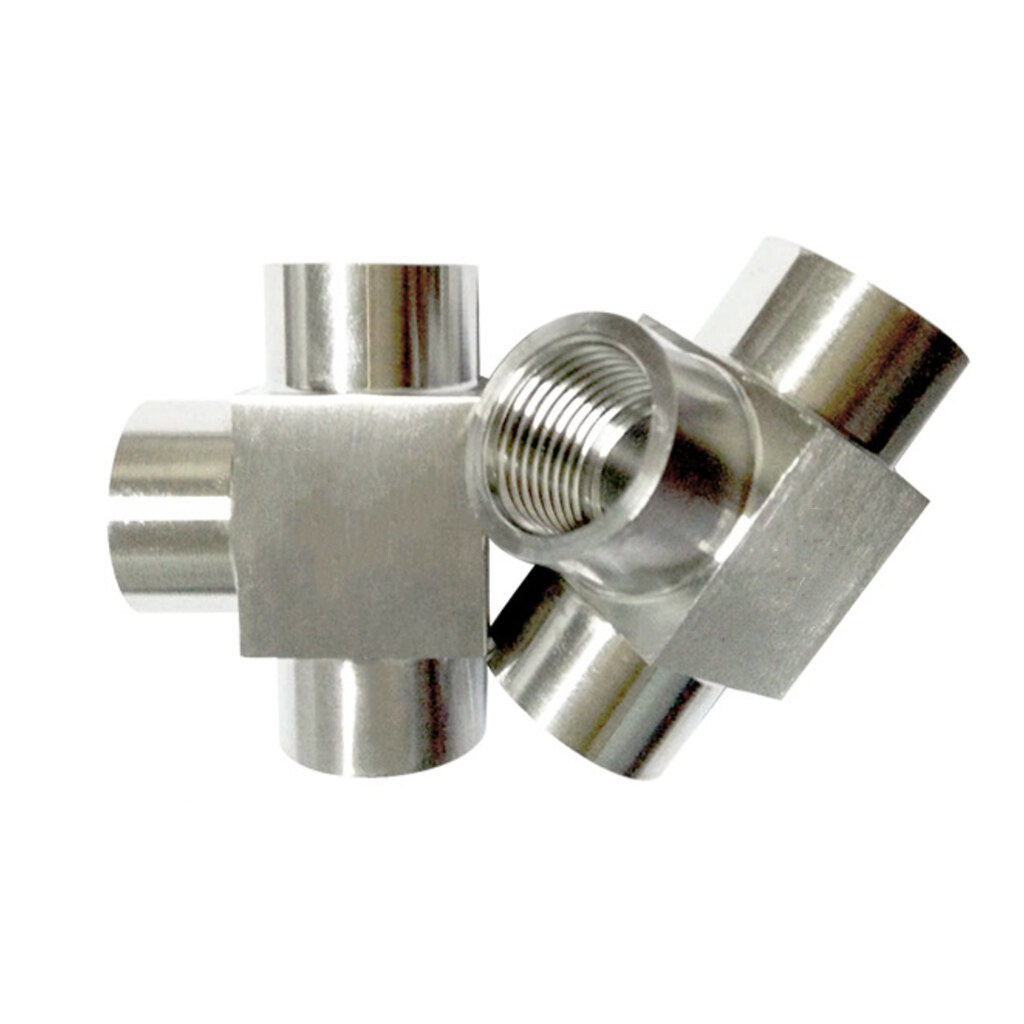

Butt weld head

The thin wall of the pipe, along with the straightforward and practical connecting method, give the stainless steel butt welding head the irreplaceable advantages over other pipe materials in terms of cleanliness, environmental friendliness, cost, and applicability. Stainless steel butt welding heads are being used in a growing number of engineering applications, and people are starting to employ them more frequently. The stainless steel butt welding head is created to meet various connecting needs. The primary way of joining is welding butt welding, and the Geer series joints are utilized for the opposite end.

Butt Weld Head

The stainless steel butt welding head is hygienic, environmentally friendly, economical and applicable, the thin wall of the pipe and the simple and convenient connection method make it have the irreplaceable advantages of other pipe materials. There are more and more applications of stainless steel butt welding heads in engineering, and their use is becoming more and more popular. The stainless steel butt welding head is designed according to different connection requirements. The main connection method is welding butt welding, and the other end is used with the Geer series joints.

The advantages of Butt Weld Head

There are various connection methods for stainless steel butt welding heads. The common types of pipe fittings are compression type, compression type, union type, push type, push thread type, socket welding type, union type flange connection, welding type and welding and traditional connection Combined derived series connection methods. These connection methods have different application scopes according to their principles, but most of them are easy to install and firm. The sealing ring or gasket material used in the connection is mostly made of silicone rubber, nitrile rubber and EPDM rubber that meet the standard requirements, which eliminates worries about the future.

Butt Weld vs Fillet Weld

The angle at which the connecting workpieces are held together is the primary distinction between a butt and a fillet weld. A butt weld is performed when the surfaces to be joined are in the same plane. A flat weld is typically used to join surfaces that are perpendicular (with an angle of 90°). As opposed to a butt joint, fillet welds don't require any welding preparation.

A triangular portion of filler metal is placed at the connection in a fillet weld joint so that it forms a 45° angle with both connected workpieces. Welding is done in numerous passes to reach the desired weld joint thickness.