Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

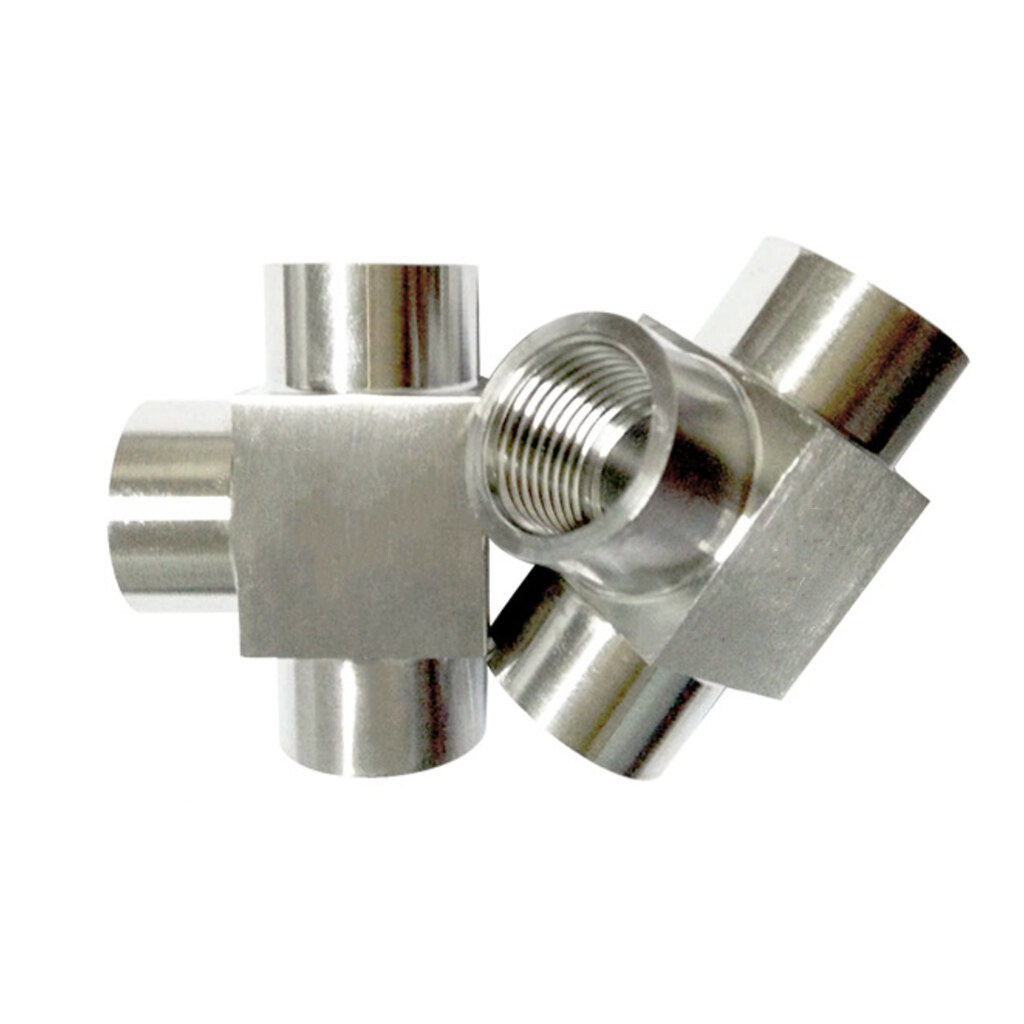

Card sleeve four-way Valves

The central connection between the steel pipe and the steel pipe is the four-way double ferrule junction. Hexagonal bar is the primary component of the raw material. The nut is silver-plated, and the double ferrule is toughened. High temperatures and pressures are no match for it. It can be used in petroleum, chemical, food, medical, pharmaceutical, ship, hydropower, water supply and drainage, smelting, energy, and other systems. It can also be used on pipes.

Card Sleeve Four-Way Valves

The four-way double ferrule joint is the middle connection between the steel pipe and the steel pipe. The raw material is made of forged hexagonal bar. The double ferrule is hardened and the nut is plated with silver. It can withstand high pressure and high temperature. It is suitable for petroleum, chemical, food, On the pipes of medicine, pharmaceutical, hydropower, ships, water supply and drainage, smelting, energy and other systems.

The installation method of Card Sleeve Four-Way Valves

1. Saw a section of seamless steel pipe with a suitable length.

2. Set the nut and card in the seamless steel pipe. At this time, pay attention to the direction of the nut and the ferrule, and carefully check not to install it backwards.

3. Apply mechanical lubricating oil to the thread and ferrule on the pre-assembled ferrule joint, insert the pipe into the joint body, insert the seamless steel pipe to the bottom, and tighten the nut with a hand tool. If the seamless steel pipe is not inserted into the bottom, it will cause oil leakage.

4. Tighten the nut to the ferrule, and then clamp the seamless steel pipe. When it reaches the turning point, the torque can be tightened very well. Once you feel the pressure point is reached, tighten the nut 1 to 2 turns further.

5. Disassemble the test fitting and check how the edge of the ferrule is inserted. There are protrusions that must fill the space at the end of the ferrule. The ferrule can be slightly rotated for 1/2 turn, but it cannot be moved axially.

6. After the final installation is completed, apply mechanical lubricant to the joint body and thread after installation. You can test the tightening force of the installation. First try to tighten 1/2 turn. If there is no loose space, it is ok.