Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

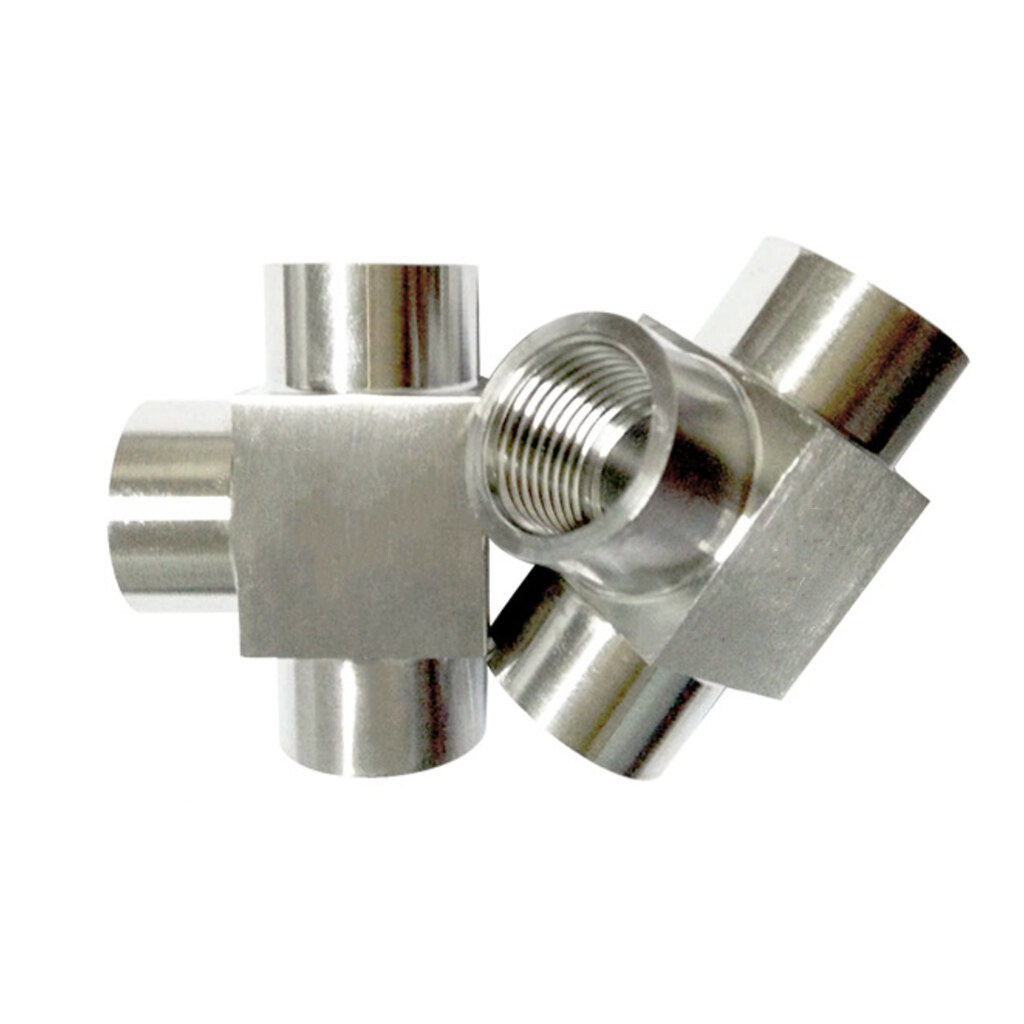

ferrule through plate joint

The inner blade of the ferrule through plate joint bites into the seamless steel pipe uniformly to establish an effective seal. There are clamps at both ends of the joint, which are worn on the end of the pipe to be connected and then clamped with a nut. The ferrule joint is extremely practical and does not require welding. It is typically utilized in the center connection of transmission pipes for gas or liquid.

Ferrule Through Plate Joint

There are clamps at both ends of the ferrule through plate joint, which are worn on the end of the pipe to be connected, and then clamped with a nut, and the inner blade bites into the seamless steel pipe evenly to form an effective seal. The ferrule joint does not need to be welded and is very convenient to use. It is generally used in the middle connection of gas or liquid transmission pipes.

The advantages of Ferrule Through Plate Joint

The emergence of ferrule through plate joints has greatly improved the sealing performance of such products. The performance of ferrule joints comes from the combination of various design features. The influence of ferrule joints on modern industry, with the petroleum, chemical, natural gas, oil refining and other industries Today, with the rapid development of China's rapid development and increasingly strict requirements on product quality, control facilities play a vital role in the quality of these liquid and gaseous products.

The ferrule through-board joint has the characteristics of reliable connection, high pressure resistance, temperature resistance, good sealing and repeatability, convenient installation and maintenance, safe and reliable work, etc. The working principle of the ferrule joint is to insert the steel pipe into the ferrule, lock it with the ferrule nut, touch the ferrule, cut into the pipe and seal it. It does not need to be welded when it is connected with the steel pipe, which is beneficial to fire prevention, explosion prevention and high-altitude operation, and can eliminate the disadvantages caused by inadvertent welding.

The maintenance of Ferrule Through Plate Joint

1. Regularly check the tightness of the ferrule joint and check it through the blowdown nozzle. If there is internal leakage, handle it according to the internal leakage handling procedures;

2. Inject a certain amount of fresh lubricating grease into the ferrule joint seat at an appropriate time, and the injection amount and frequency are determined according to the frequency of ferrule joint activities.