Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

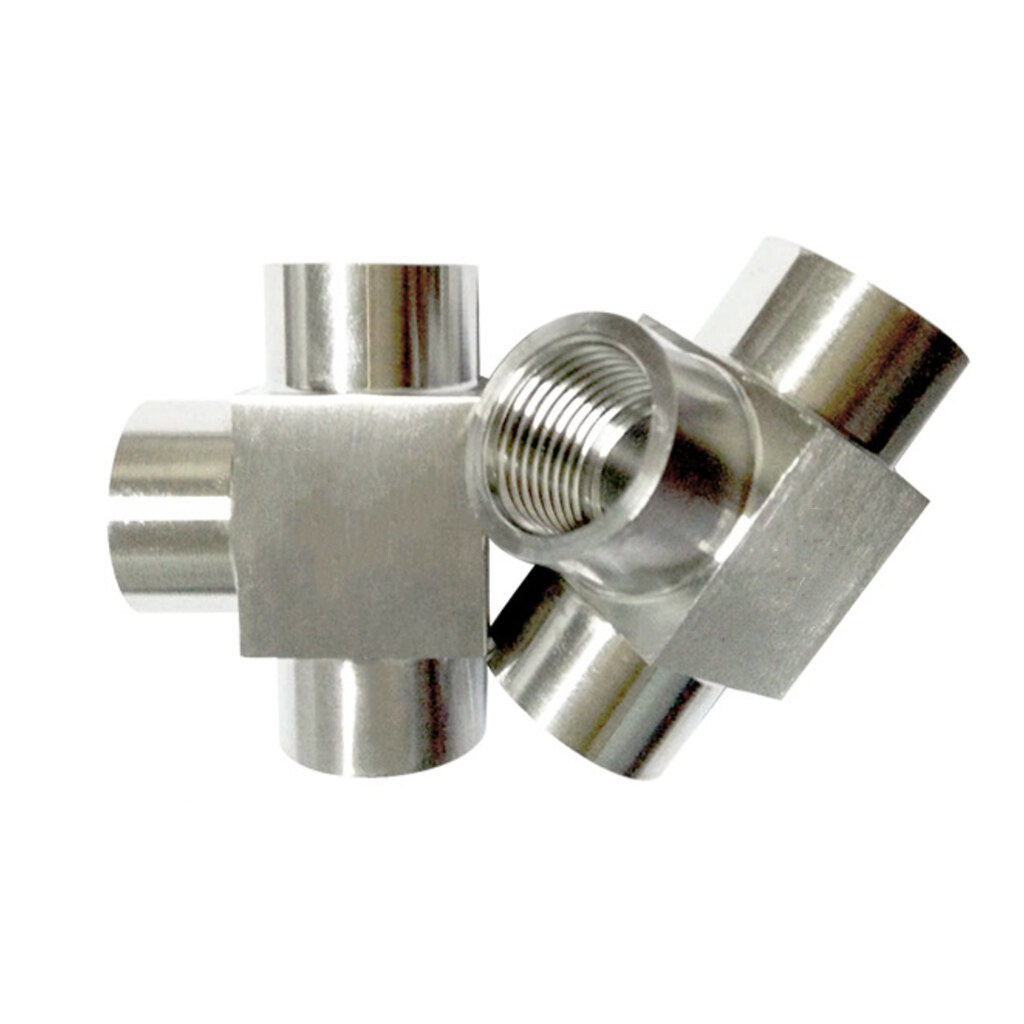

Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

Compressed air quick couplings with high performance and safety will increase tool performance and conserve energy. An exhaust disconnect is a feature of the safety fast coupler that prevents kickback and lowers noise levels for safer operation.

Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

High performance, high safety compressed air quick couplings will save energy and improve tool performance in compressed air applications. The safety quick coupler features an exhaust disconnect to eliminate kickback and reduce noise levels for safer operation.

Pneumatic quick couplings continuously reduce pressure drop and increase air flow to reduce energy consumption for customers. While producing compressed air requires a lot of energy, the efficiency of compressed air connectors and fittings becomes even more important. For an energy-efficient compressed air system, you need to make sure it's leak-free and uses high-quality, high-flow, low-drop-drop connectors. An optimized compressed air system is a sustainable option that provides high and sustained tool efficiency.

The advantage of Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

It can be easily installed manually. No tools or glue required. In addition, quick couplings can also provide different pipe connections, pipe sizes and threads to achieve the required effect.

The application of Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

Quick connectors for connecting pneumatic tools such as air pipelines, air compressors, grinders, air drills, impact wrenches, air screwdrivers, etc.

The precautions of Male Threaded Stainless Steel Pneumatic Push Connection Quick Air Pipe Fittings

Please do not use it for purposes other than quick fluid connectors.

Do not use for fluids other than the applicable fluids.

Please do not connect with quick fluid connectors produced by other companies.

Do not exceed the maximum working pressure when using.

Do not use it outside the operating temperature range to prevent wear or leakage of the sealing material.

Do not artificially hit, bend, stretch, and prevent damage.

Do not use in places where metal powder or sand dust is mixed to prevent poor work or leakage.

Such as attachment of sundries will cause poor work or leakage.

Do not disassemble the quick connector.