Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

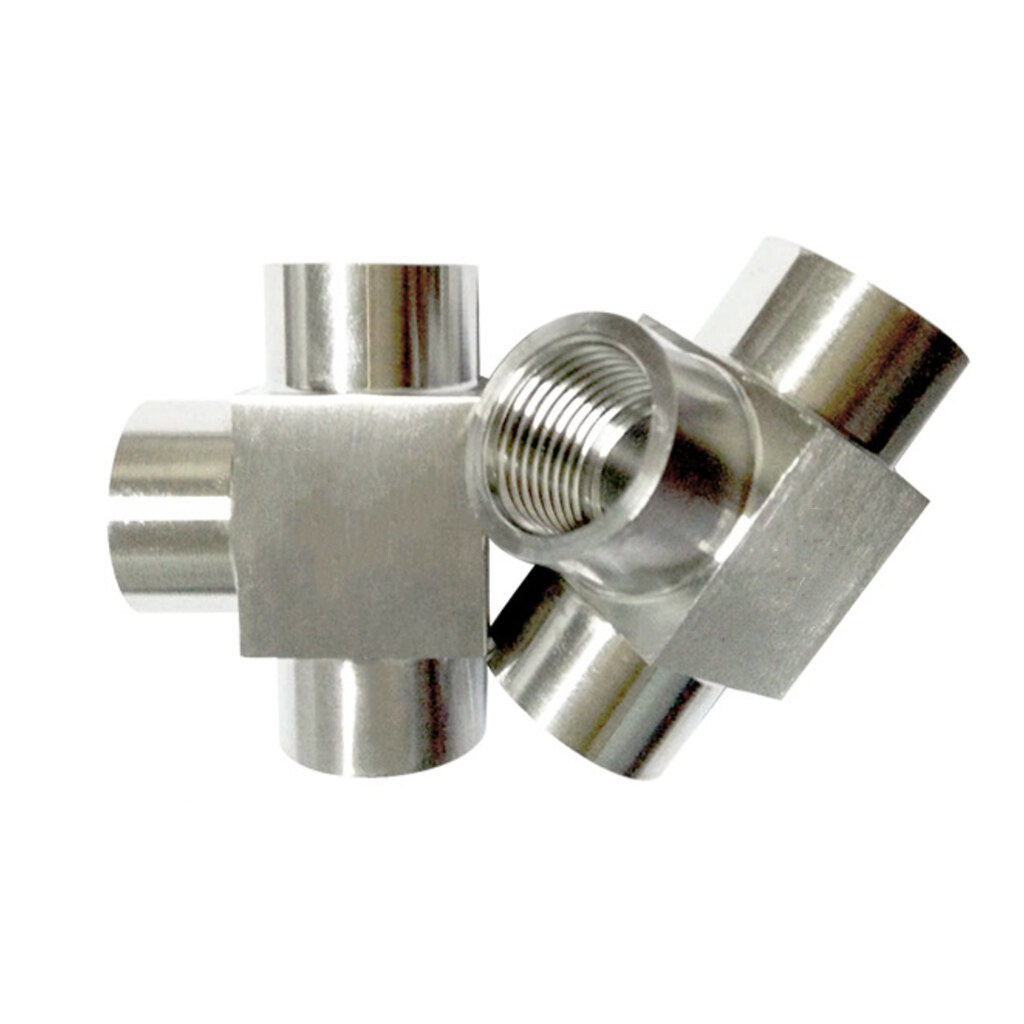

Pneumatic Stainless Steel Male Elbow L Type Connector Fittings

The stainless steel hose joint is attractive and has a small overall footprint. It is airtight thanks to its lack of air holes, steel pipes, and box connections. The equipment, box body, steel pipe, hose caliber, and thread are only a few examples of variables that might affect specifications and sizes. The hose (steel pipe) is attached to one end, and the switch box, motor, bridge, etc. are connected to the other end, which is externally threaded.

Pneumatic Stainless Steel Male Elbow L Type Connector Fittings

The stainless steel hose joint has a beautiful appearance and a compact structure; it has no air holes, steel pipes, and box connections, and has the advantages of good air tightness. Specifications and sizes can be changed arbitrarily according to equipment, box body, steel pipe, hose caliber and thread. One end is connected to the hose (steel pipe), and the other end is externally threaded to connect the switch box, motor, bridge, etc.

The advantages of Pneumatic Stainless Steel Male Elbow L Type Connector Fittings

1. Corrosion resistance - made of stainless steel 316, corrosion resistance, very hygienic, safe to use.

2. Prevent liquid accumulation - because the hose and joints are tightened, it can prevent the hose from falling off and fluid leakage, which is very safe.

3. Save cleaning time——Because of the structure that the liquid is not easy to accumulate, there is no need to disassemble and clean, which greatly shortens the cleaning time.

4. Anti-leakage and detachment--Because the hose and joints are tightened, it can prevent the hose from falling off and fluid leakage, which is very safe.

The choose methods of Pneumatic Stainless Steel Male Elbow L Type Connector Fittings

1. The pressure of the liquid: the pressure of the fluid is also the hub of the selected joint;

2. The structure of the automatic switch valve: For the structure of the valve, there are two-way switch type, one-way switch type and two-way open type, so please pay attention;

3. The type and temperature of the fluid vary according to the fluid, the suitable body material and sealing material are different. This is because fluid flows out of the piping except for the two-way switch type at the time of separation. If it is made of steel, if it is water, choose brass or stainless steel;

4. For the shape and size of the installation, please determine the type and material of the joint, and the assembly shape and size corresponding to the characteristics of the piping;

5. The use environment of the hose joint: consider the type of joint, body material, and sealing material selected in combination with the humidity premise of the use environment, the condition of dust, and the use environment that is easy to corrode.