Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

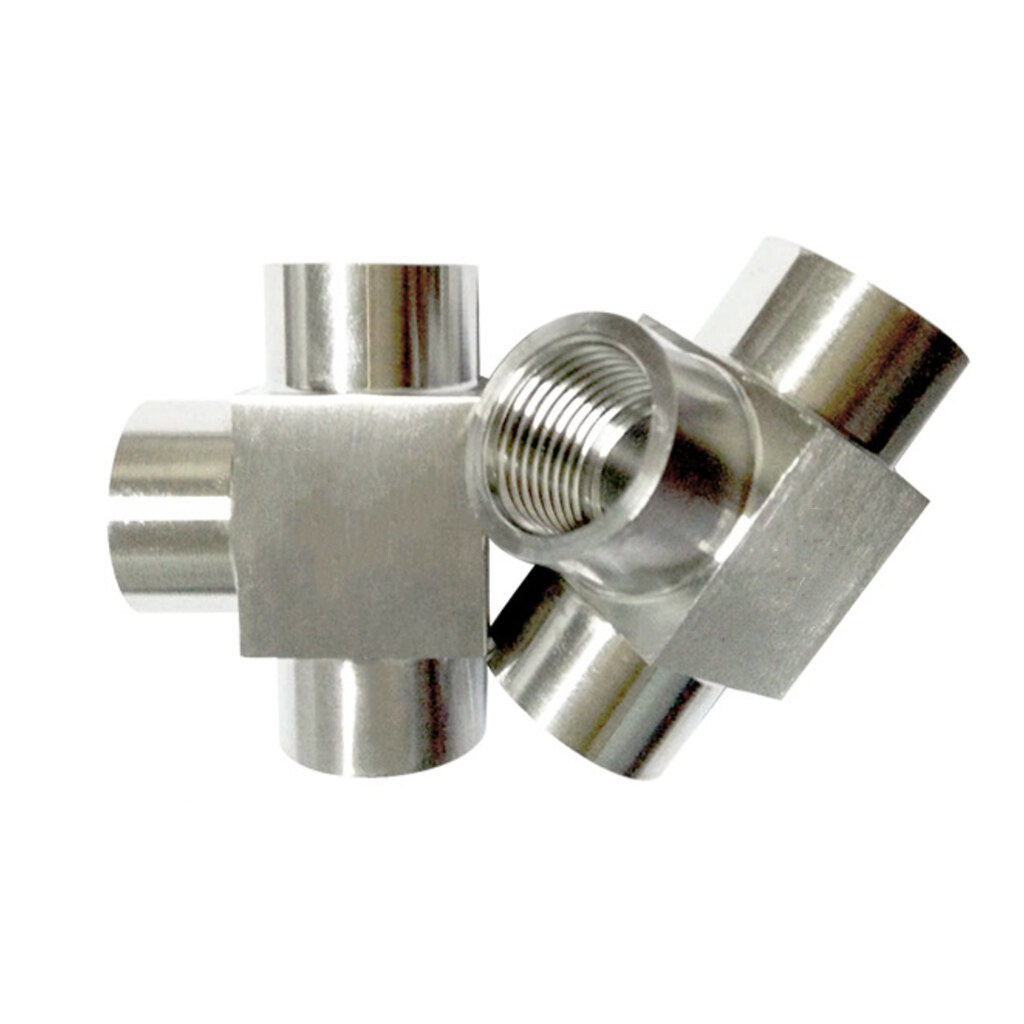

Stainless Steel Double Ferrule Elbow Fitting Elbow Fitting

The steel pipe is inserted into the ferrule, secured with the ferrule nut, brought in contact with the ferrule, and then the pipe is cut into and sealed. When it is connected to the steel pipe, it does not need to be welded, which is advantageous for high-altitude operation, fire prevention, and explosion prevention. It can also eliminate the drawbacks brought on by accidental welding.

Stainless Steel Double Ferrule Elbow Fitting Elbow Fitting

The working principle of the double ferrule joint is to insert the steel pipe into the ferrule, lock it with the ferrule nut, touch the ferrule, cut into the pipe and seal it. It does not need to be welded when it is connected with the steel pipe, which is beneficial to fire prevention, explosion prevention and high-altitude operation, and can eliminate the disadvantages caused by inadvertent welding. Therefore, it is a relatively advanced connector in the pipelines of automatic control devices in oil refining, chemical, petroleum, natural gas, food, pharmaceutical, instrumentation and other systems. Suitable for oil, gas, water and other pipeline connections.

The features of Stainless Steel Double Ferrule Elbow Fitting Elbow Fitting

1. Good sealing

2. Pressure-resistant and durable

3. Not easy to rust

4. Wide range of use

* Connectors for connecting different types of pipes or fittings

* The fitting is connected to the pipe at one end and has a female connector at the other end

* Chemically hardened 316 stainless steel has higher strength and greater corrosion resistance than untreated stainless steel

* Double ferrule compression fittings for leak-tight sealing in high pressure applications

* For stainless steel tubing

How do you connect fittings accurately and securely every time for safety?

1. Make sure the tube is ready. Make sure the tube is clean. Deburring and tube hardness and conforming to tube fitting specifications.

2. At the bottom of the fitting behind the shoulder.

3. Tighten the nut until it can no longer be tightened by hand

4. Mark the nut at 6:00 with a marker, and turn the nut 1 1/4" with a wrench to tighten

What happens if we install a fitting that is over-tightened or over-tightened?

First, you may have to throw out accessories. Tubing may have to be replaced, which can result in considerable time and expense. There are many more possibilities regarding security issues. The media flowing through our pipelines may be under high pressure. May be high temperature. It can be harmful and corrosive chemicals.