Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

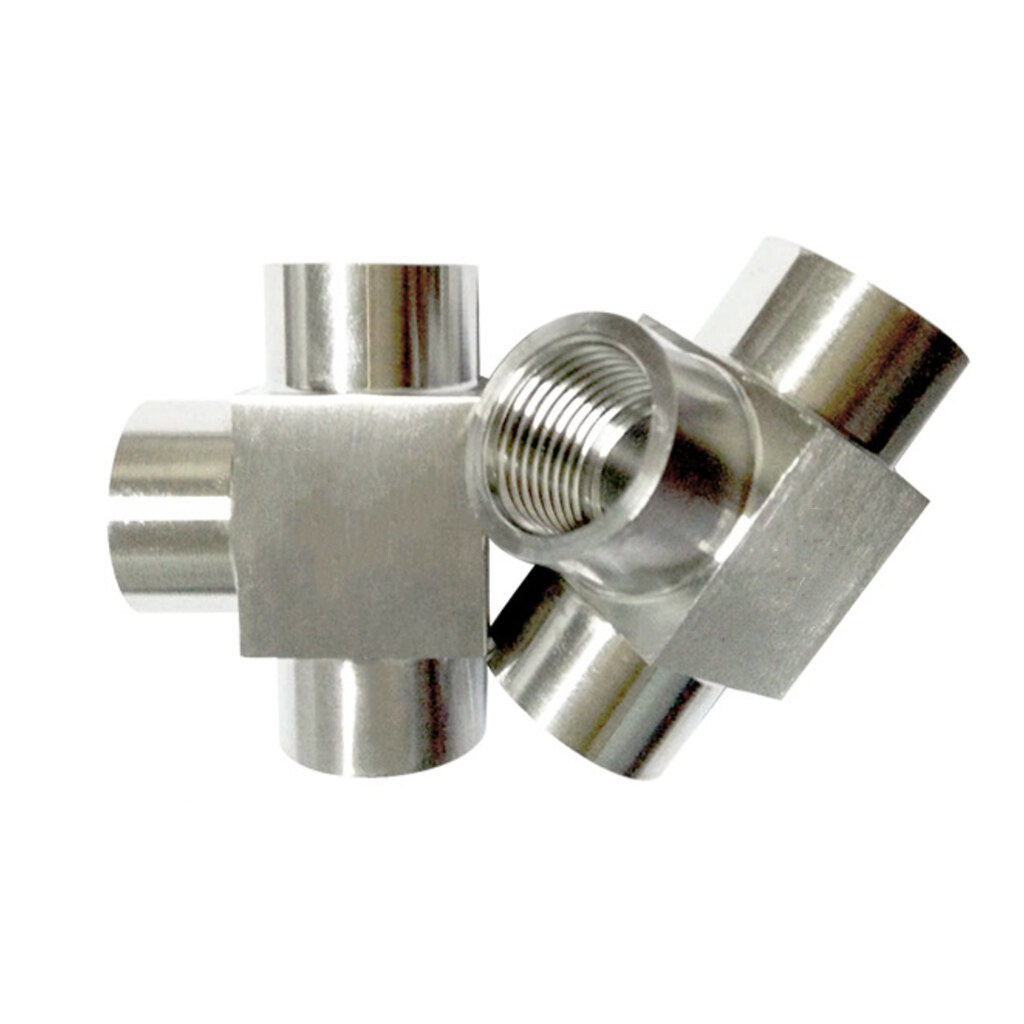

Stainless steel ferrule five-way ball Valves

A spherical valve core is utilized, together with a spherical sealing ring, to ensure the sealing performance between the valve body and the valve core in the stainless steel five-way ball valve. To guarantee the tightness of the connection between the valve core and the valve sleeve, the valve core and the valve sleeve must be connected via a compression spring.

Stainless Steel Ferrule Five-Way Ball Valves

The stainless steel five-way ball valve includes a valve body and a valve core, a spherical valve core is used, and a spherical sealing ring is used to ensure the sealing performance between the valve body and the valve core. The valve core and the valve sleeve need to be connected through a compression spring, so as to ensure the tightness of the connection between the valve core and the valve sleeve.

The main function is reversing, and it is widely used as a relatively advanced connector in the pipelines of automatic control devices in oil refining, chemical, petroleum, natural gas, food, pharmaceutical, instrumentation and other systems. Suitable for oil, gas, water and other pipeline connections.

The features of Stainless Steel Ferrule Five-Way Ball Valves

1. The structural design fully considers the reduction of dead volume, and it can be used in the fully open or semi-closed position.

2. During the service life of the valve, by re-tightening the inner gland of the valve, the adjustment of the sealing specific pressure can be realized, so as to achieve the purpose of resealing or approaching the high pressure index.

3. When using for the first time, due to overcoming static friction, the torque of the handle may be too large, which is not a malfunction. In addition, the ball valve has a higher operating torque in the gas medium flow path than in the liquid medium flow path.

4. Each ball valve has passed the 7MPa nitrogen or air test pressure test.

5. Wide range of operating temperature. This relies on our unique manufacturing and handling technologies. The temperature range covers -10~90℃.

6. Up to 5 years of storage period while sealing and maintaining function. This is due to the unique prestressed manufacturing and processing technology.

7. High pressure resistance 17.2MPa (at 25°C environment), the conventional connection metric ranges from 3 to 12 mm, and the imperial system 1/8, 1/4.

8. The international mainstream general pipe connection method.